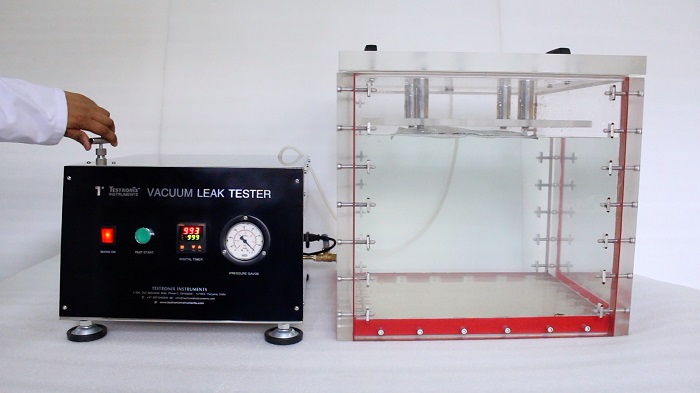

A vacuum leak tester or vacuum testing machine is an essential tool for those sectors where leak-tight seals, packaging, or constituents are of extreme importance. It helps to test for leaks in a product by measuring the pressure decay in a vacuum environment.

Packaging Industry

The packaged product is sealed properly in a manner that air, moisture, and other contaminants have not penetrated the package.

Example – Chips and snacks and vacuum-wrapped meat in the food packaging sector require tight packaging to enable long preservation time and freshness. Vacuum leak testing is applied to make sure that there are no tiny holes or leaks in the package that could easily trigger spoilage.

Pharmaceutical Industry

This testing confirms that the drug and medical product are in sealed and sterile vacuum conditions.

Example – Temperature-sensitive drugs like vaccines are packed in evacuated sealed containers. The vacuum leak tester for bottles ensures the seal is tight and won't create any opportunity for contamination to compromise the efficacy of the drug.

Medical Industry

In the medical industry, the sterility of medical devices and the packaging they come in can range from syringes and IV bags to surgical instruments.

Example – Syringes and surgical instruments require a hermetically sealed package to preserve the sterility of the instrument. A vacuum testing machine ensures that the package for those products is sound, with no pinhole-sized leaks that would allow air to pass through, compromising sterility or safety.

Automotive Industry

Seal leak testing on auto parts, so they seal perfectly and serve their intended purposes.

Example – Most car parts need tight seals, such as fuel tanks and air-conditioning systems, for efficiency and proper safety to be observed. Thus, it makes use of a Vacuum Leakage tester to test a possible leak from a fuel tank or an engine system that may cause performance problems or safety issues.

Food and Beverage Industry

A vacuum test machine aims to tighter seal on food packaging to ensure that the food remains fresh and contamination-free.

Example – Vacuum sealing canned goods, beverages, and pre-packed snacks in the food and beverage sectors to remain fresh. A vacuum leak testing equipment will check if there is an airtight seal that would prevent spoilage or contamination from occurring.