Reviewed by Anurag Mishra (Sr. Technical Consultant)

Now let's discuss one situation we have all been in at some time, anxiously waiting for your package only to unpack it and find that your fragile item is broken or your electronics are damaged. Frustrating, right? Now imagine the same experience multiplied hundreds or thousands of times with deliveries. That's where the Drop Tester comes to the rescue with its cape of scientific accuracy.

No, don’t just trust my words, in fact, let's dig into why this unsung hero of packaging is worth the most power-packed consideration. After all, this blog is like your backstage pass to understanding why you can trust a drop tester to safeguard goods, customers, and even your brand.

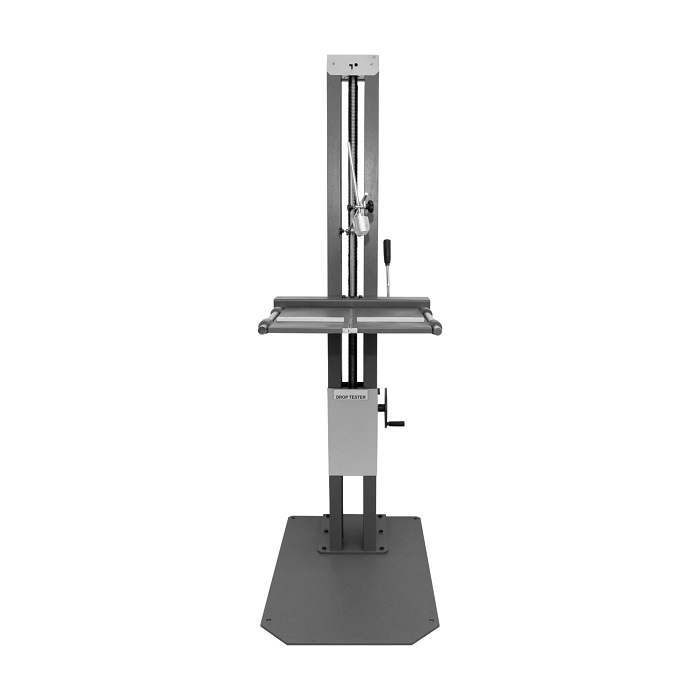

This means, imagine a box that you're holding, and you just drop it. The Drop Tester does exactly that, but far more accurately and uniformly. This magical machine simulates the impacts and drops that your package may experience during its long journey whether it's how the delivery guy tosses it on the truck or just drops it because he is piled up with loads. It's like sending your package out there on a little crash course to see how it survives.

You could try doing it the manual way (you know, for fun), but a Drop Tester provides repeatable and standardized results without relying on how well you can drop stuff. And no risk of dinging your floor by accident either!

The most obvious and the first reason you would need a drop tester is to make sure that your product arrives in one piece. It's not only fragile items, such as glass or porcelain, but even the most robust of products are at risk of getting damaged with continuous drops, impacts, or bumps that might occur in transportation.

Let that first impression be 'Wow!' of a perfectly delivered product, not of a broken one. Damaged products don't just ruin a customer's day—they might ruin his perception of your brand forever.

When you assure packaging integrity by making use of a drop tester, you're certainly less likely to receive product returns but are also most likely to possess satisfied customers. That's like wrapping happiness with a layer around your product. ".

It does sound quite contradictory to think about being known for great products versus having a great returns customer service team, doesn't it?

And now it gets serious. When you get to the doorstep of your customer and your product doesn't look so good, you are paying a pretty penny. You will be covered by return shipping and replacement costs and possibly loss of future sales from irate customers. A drop tester can reduce those unwanted costs by fine-tuning your packaging. Invest in testing today, and save on disasters tomorrow.

We all love to honor rebel spirits, but it's actually a good thing to follow the rules, as far as packaging goes. There are lots of industries that have regulations on packaging, to set down specific drop test requirements, especially for hazardous materials or high-value commodities. You don't want to be flying under the radar here.

A drop tester ensures that your packaging is in compliance with international standards. This will give you a good conscience—and it keeps away all those dreaded fines.

Using a drop tester protects your products, but saves the planet too. How? Optimizing packaging helps avoid waste. Knowing how much protection is required, kills over-packaging, and excess cardboard, plastic, or bubble wrap in the box.

Efficient packing = less material consumption = less waste. In addition, fewer products damaged mean less rerouting, hence less fuel used and money spent. This, surely, is a profitable deal!

Ever heard the phrase "dress for success"? Well, the packaging is your product's dress code. If your package can withstand the drop test, that tells your customers, "Hey, we cared about the quality from start to finish.".

And who can forget the social media effect? Viral content of a damaged product arriving can severely impact your reputation, whereas happy customers use your product with no issues, showcasing it to the world, and thus strengthening your brand image. A drop tester is your protector from the former.

Conclusion: Drop the Mic (or the Package)

Every detail counts, today in such a competitive marketplace, from packaging materials, and quality, to how well your products can be shipped. A drop tester is your ticket to ensuring safety, and customer satisfaction and saving you money over the long term.

FAQs: Because Curiosity Never Dropped the Ball!

It's quite incredibly simple. A drop tester puts your package up to a predetermined height and drops it in a controlled manner. It can drop from almost all angles, and at different heights, giving you an overall idea of how well the packaging might perform.

Not all items have to undergo testing, but you can test a sample. Test one or more packages, from a production batch, to be sure that they adhere to the safety requirements.

The height you're going to use will depend on how your product is going to ship. For example, if it's going to the airship, you might need to test at a higher height. Industry standards, such as ISTA, can provide you with specific recommendations based on your product and shipping method.