Reviewed by Anurag Mishra (Sr. Technical Consultant)

In the microbiology industry, controlling contamination can be a challenging sometimes. In this industry disinfection and cleanliness is a critical step. However maintaining sterilization processes for laboratory instruments, glassware and various instruments. Unclean instruments can lead to errored calculations and several other mistakes. Where as using he traditional methods for sterilization can be stressful and also isn’t suitable for all of the instruments.

Where there is a problem there is a solution and solution to this problem is the Testronix Hot air oven. The hot air oven is an all-rounder it can look after all the temperature related procedures. It can used for sterilizing various instruments that cannot be traditionally sterilized like powders, oils or metal instruments in the microbiology field. You can also utilize the hot air oven for drying purposes as it uses heated air in its working it can decontaminate and dry the instruments without cursing any damage.

A hot air oven in microbiology is a laboratory equipment utilized for sterilization of glassware and other equipment by dry heat. Working at temperatures of 160°C to 180°C for 1 to 2 hours, it efficiently kills microorganisms such as bacteria and spores by oxidizing their cellular constituents.

Unlike steam heat processes such as autoclaving, hot air ovens are suitable for materials that support high temperatures but are moisture-sensitive, including powders, oils, and metal instruments. The process guarantees a contamination-free environment necessary for precise microbiological applications.

The working principle of a hot air oven in microbiology relies on dry heat for the sterilization of laboratory materials and equipment. The oven distributes hot air evenly in an insulating chamber, using a fan or blower to provide uniform temperature distribution. The dry heat circulates the contents within and inactivates microorganisms through oxidative mechanisms that weaken proteins and break down cell membranes.

For successful sterilization, the oven is set between 160°C and 180°C for 1 to 2 hours, depending on the load and material. Here is the whole procedure of a Hot Air Oven in Microbiology:

Preparation of Materials: Sterilize all the glassware or instruments by drying and cleaning them. Wrap them in aluminum foil or put them in appropriate containers which facilitate penetration of heat.

Loading the Oven: Stack the contents of the oven in a manner that enables the circulation of air between them. Overloading must be avoided so that there is a uniform distribution of heat.

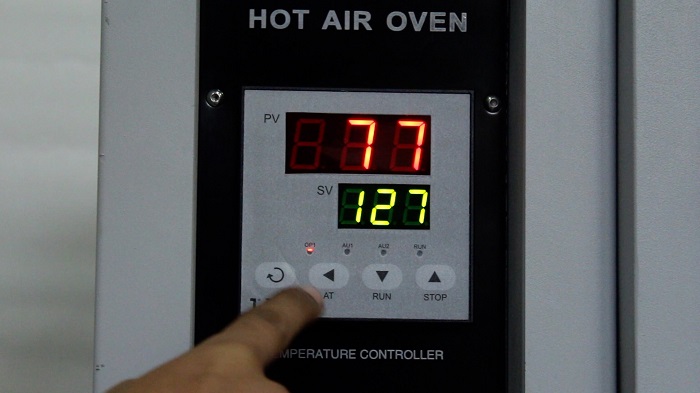

Setting the Temperature and Time: Securely close the oven door, then set the temperature needed—usually between 160°C and 180°C—and the correct sterilization time (typically 1 to 2 hours based on the load).

Heating Phase: Let the oven heat to the specified temperature and hold for the given time. Do not open the door during this period as it will lead to heat loss and weaken sterilization.

Cooling Down: Once the time is over, shut off the oven and let it cool slowly to room temperature before opening. Early opening of the door may subject glassware to thermal shock.

Unloading: Remove the cooled sterilized contents carefully with the aid of heat-resistant gloves. Place them in a sterile storage area or immediately use them.

Hot air oven diagram in microbiology involves various components includes double-walled, metal casing, adjustable shelves, heating elements, etc. Additionally, adjustable shelves inside position the materials for sterilization and are engineered for efficient dry heat sterilization.

Heating elements surround the chamber, and a self-contained fan ensures even airflow. A heat sensor and thermostat or digital controller control the heat, with a timer and indicator lights aiding in operation. The door is closed by a heat-resistant gasket to ensure that heat is not lost during sterilization.

A hot air oven is a critical piece of equipment in microbiology labs to sterilize equipment and materials using dry heat. It ensures lab equipment is free of microbial contamination, making it critical in ensuring that microbiological experiments are accurate and reliable. Unlike moist heat applications, it is best suited for materials that are tolerant of high temperatures but not humidity.

Sterilization of glassware such as Petri dishes, test tubes, and pipettes

Dry sterilization of metal instruments like forceps and scissors

Decontaminating powders and oils that cannot be autoclaved

Providing aseptic conditions for microbiological tests

Safe storage of sterilized items until use

Testronix, is a leading provider of high-end and technically sound lab testing instruments for efficient quality control. We offer our versatile Hot air oven to various industries, including microbiology. We are committed to precision and quality from the past 11 years and we have been serving quality instruments to our 1200+ valuable costumes.From big brands to small and medium enterprises we have worked with them all. Some of our renowned clients include: TVS, Blue Star, Maruti Suzuki, asian paints, The Aditya Birla group and the list just goes on. With our specific and customer-centric products we have gained credibility through our customers and their feedback.

“The entire team at Testronix is highly professional. They provide timely delivery with world class features in all their instruments. They also provide customised instruments as per the needs of the user which no other dealer/trader can provide. We are very much satisfied with their products”

- The PepsCo

“ We are highly impressed with the Quality and support Testronix has provided. Testronix has set up our entire quality testing laboratory and we are fully satisfied with all their instruments. We highly recommend this brand”

- The Aditya Birla Group

Hot Air Ovens are specially designed to provide uniform and controlled dry heat throughout the chamber for efficient sterilizing and other purposes. For the Microbiology field specifically this Hot air oven can be used to sterilize the materials that cannot be sterilized in the traditional manner and can be used for the dying purposes of different materials and instruments through the dry heat as it won’t lead to any damages to the product.

Heating Element: This is the fundamental and the most important component of a Hot air oven, it is responsible for generating the dry heat. It is made to exude uniform dried heat in the chamber.

Thermostat: The thermostat enables you to measure and set precise temperatures. You can control the overall temperature of a hot air oven through it.

Insulated Chamber: The insulated chamber is manufactured in such a way that it retains the heat in the chamber and also does not let the outer environmental temperature affects the inner conducting procedure.

Our Hot Air Oven is available in two different sizes 18 inch x 18 inch x 18 inch and 24 inch x 24 inch x 24 inch with temperature ranges 250 degrees and 300 degrees. Along with a with a graphical LCD Display.

FAQ

A Hot Air Oven is a versatile instrument that can be used for many purposes. It can conduct efficient testing for almost all types of material you can measure the effect temperature does on the sample. You can also use it for drying purposes.

We have two different models of Hot Over Oven and their temperature ranges upto 250 egress and 300 degrees.

A Hot air oven can test, assess, sterilize any material. Make sure to not put any flammable material in the oven.

If you are a microbiology expert you must have understood the importance of Hot air oven by now. So don’t waste your time and book a free demo today to understand the whole process and take yourself to another level.

To book a demo contact us at:

Phone: +91 9313 140 140