Reviewed by Anurag Mishra (Sr. Technical Consultant)

A muffle furnace is a vital high-temperature laboratory and industrial testing instrument designed to analyze the non-combustible and non-volatile content of materials. It provides a contamination-free heating environment and ensures accurate material testing. Commonly used in research labs, metallurgy, and quality control departments, muffle furnaces can reach temperatures up to 1200°C, delivering precision heating for materials such as glass, ceramics, and enamel coatings.

In this post, you will learn everything about a muffle furnace, its working, and its applications in various industries.

A muffle furnace is a high-temperature heating device used for controlled thermal processing. It works by enclosing the sample within an insulated chamber, preventing direct contact with combustion gases or fuel. Due to their versatility, muffle furnaces are commonly used in material research, pharmaceutical testing, forensic analysis, and quality control processes.

These furnaces come in different sizes and designs to suit the varied requirements of laboratories and industrial use. Most contemporary models have programmable temperature controls, quick heating, and energy-saving insulation, providing precision and cost savings across a range of industries.

· A muffle furnace is an unopened chamber that uses an elevated temperature heating coil to heat the element.

· The insulating material wrapped around the coil serves as a muffle, preventing heat from leaking.

· The material being heated is separated from the fuel and burnt by-products.

Muffle furnace is used for various purposes like heat treating materials, burning, blending, chemical analysis, fusing, and Air treatment. A muffle furnace's key property is that it has an isolated ignition and heating chamber. Today a muffle furnace is a front-opening box used for high-temperature applications such as glass fusion, making enamel coatings, and fusing.

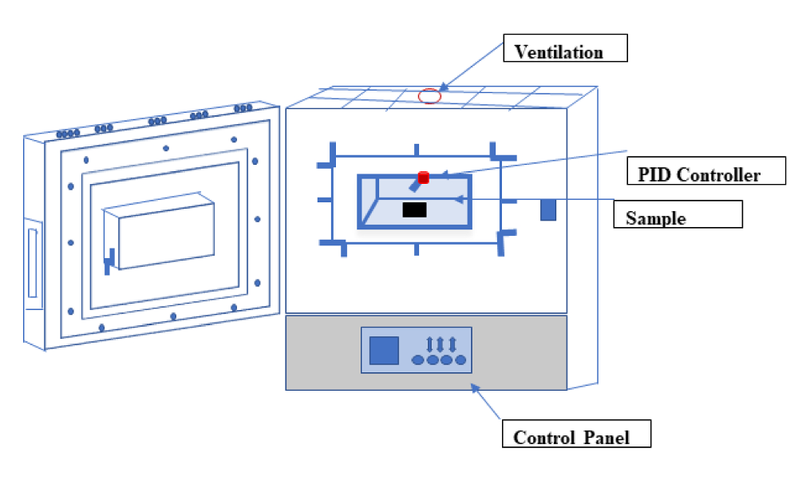

The muffle furnace diagram includes the key components: an insulated heat chamber, a heat-producing device that circumscribes the chamber, temperature control regulation, and electric connections. The heat-producing device generates heat, and the chamber keeps materials inside out of direct contact with the heat source, warming them indirectly with a stable temperature.

· A heated chamber: Assures heat transfer by avoiding temperature variation that could harm the test results.

· A temperature controller: It is used to maintain and control the temperature within the heat chamber. It instantly reduces the power if the temperature overtakes the set limit.

· A safety door switch for operator safety: A safety door switch in a muffle furnace is a protective concept used to safeguard the operator, assuring the furnace can only operate when the door is completely shut. This switch cuts off power or stops the furnace from heating if the door is open, minimizing the risk of contact with high temperatures or dangerous gases.

· High-quality heating system: A good quality heating system is important to maintain the temperature and minimize the risks.

· Temperature controller – Temperature up to a maximum of 1600 degrees Celsius.

· Exhaust pipe fitted with the rear side of the furnace.

Muffle furnace work on the principle of indirect heating, where the heating materials are located outside the furnace chamber, and the material that needs to be heated is located inside the isolated chamber known as a muffle. The muffle is made up of a clay material like alumina, which can stand up to high temperatures and is opposed to chemical decomposition.

As soon as the muffle furnace is switched on, an electric current is passed by the heating elements, which then warm up and emit heat toward the muffle, the muffle takes in the heat and becomes a blaze.

The temperature that resists in the muffle is controlled by a temperature controller, which examines the temperature and modifies the strength transferred to the heating elements accordingly. This assures that the material is burnt to the given temperature without overheats.

Muffle furnaces are used for high-temperature applications such as glass fusion, making enamel coatings, and fusing.

The working principle of muffle furnace relies on thecontrolled heating of materials in a climate-controlled, deoxygenated environment, working of the muffle furnace includes:

A muffle furnace works on the Law of conservation of energy and the principles of indirect heating and temperature control.

A Muffle furnace is used for processes like metal testing, ash content analysis, sintering, and annealing. The furnace helps heat materials without direct contact with flames, ensuring precise temperature control for various applications. Here are the more details on the applications of Muffle Furnace –

Muffle furnace temperatures range from 1,000°C to 1,800°C however, the ultimate temperature depends on the category of heating materials like metallic, silicon carbide, etc.

· Metallic wire heating elements: These elements are the most general type of elements and can achieve temperatures from 1000 degrees Celsius to 1200 degrees Celsius.

· Silicon Carbide heating elements: The temperature can achieve temperatures up to 1600 -degrees Celsius.

· Molybdenum disilicide heating elements: Here, the temperature can range up to 1,800°C.

Standard muffle furnaces generally have a temperature range between 300°C (572°F) to 1,200°C (2,192°F). These are appropriate for a broad range of applications, like burning, tempering, and basic heat treatment processes.

Testronix Instruments is one of the prominent companies in India that delivers quality-assured testing machines at the PAN India level. With the dedication and hard work of experts, and the R & D team, the company is efficient in bringing the best quality testing instruments with the custom facility. Muffle Furnace by the company is one of the best-selling testing tools that are available with a user-friendly operating system, quality material, and precise structure. Choose Testronix for the best experience in

In conclusion, muffle furnaces play an important and serious role in current industries, providing a trustworthy, accurate, and protective strategy for manufacturing materials at high temperatures. Their ability to create a separate and managed environment makes them essential for many applications, assuring reliable outputs and improving efficiency across sectors.

To know more about the features, working, benefits, and availability of Muffle furnaces in your area, connect with us. We are available at +91 9313140140 or mail us for a quotation at info@testronixinstruments.com.