Reviewed by Anurag Mishra (Sr. Technical Consultant)

A hot air oven is an essential tool used in laboratories and industries for sterilizing products such as glassware and sealed containers. It uses a thermostat to control the temperature and dry heat to ensure the products are free from contamination and safe to use.

A hot air oven is a type of forced convection oven that uses hot air to circulate around the specimen, heating it evenly on all sides. It is often used in laboratories to sterilize equipment and supplies.

A hot air oven works by circulating hot air around the specimen, heating it evenly on all sides. The temperature inside the oven is controlled by a thermostat, and the fan speed can be adjusted to control how quickly the temperature elevates. You can read more on the uses of hot air oven in testing laboratory.

Hot air ovens are often used in laboratories to sterilize equipment and supplies. The high temperatures of the oven can kill bacteria and viruses, making it an essential tool for keeping laboratory environments clean and safe.

A hot air oven is a laboratory equipment designed for dry heat sterilization, drying, and thermal testing. It operates through forced convection, circulating hot air uniformly within an insulated chamber to ensure even heating of samples. This makes it ideal for sterilizing glassware, metal instruments, powders, and other heat-resistant materials that cannot be treated with moist heat.

Hot air ovens are widely used in microbiology labs, pharmaceutical industries, and research facilities due to their efficiency, reliability, and ability to maintain precise temperature control for contamination-free results.

The hot air oven uses are primarily associated with sterilization and drying in laboratory settings. This device utilizes dry heat to effectively eliminate microorganisms such as bacteria and fungi from various lab materials. Unlike moist heat sterilization methods, a hot air oven is suitable for items that may be damaged by moisture. It is widely used for sterilizing glassware, metal instruments, powders, and other materials that require a controlled, high-temperature environment without the presence of steam.

Sterilization of laboratory glassware such as test tubes, Petri dishes, powders, flasks, and pipettes

Elimination of microbial contamination from metal instruments and heat-resistant tools

Dry heat testing to assess the thermal stability and resistance of materials

Drying of chemical samples and lab materials after washing or experimentation

Sterilization of powders, oils, and other substances unsuitable for moist heat

Baking and curing of lab substances requiring specific temperature conditions

Hot air ovens are used for testing food items, pharmaceutical products, and consumable materials

Hot air ovens can be used for research scenarios such as chemistry, biology, or material science

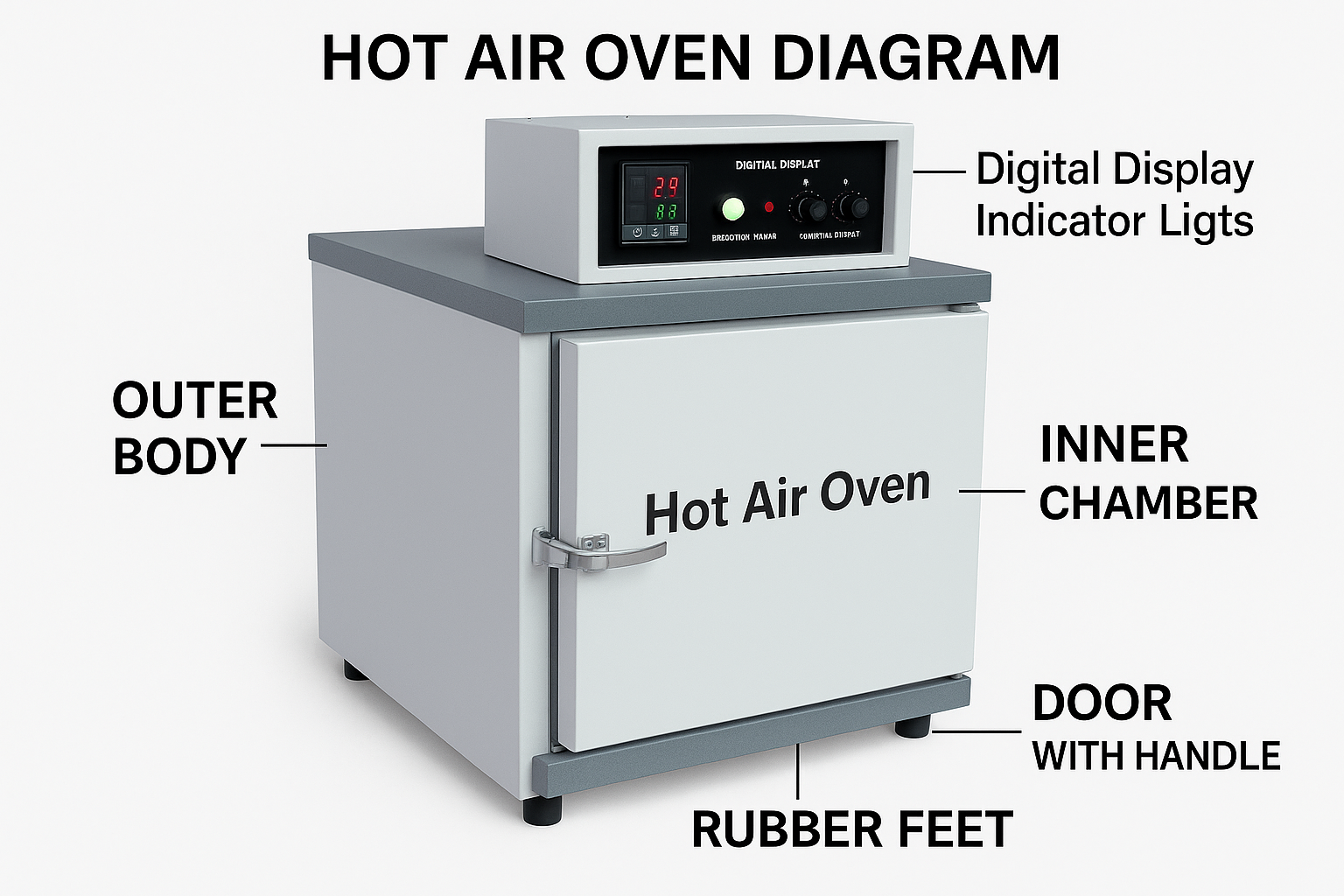

The hot air oven diagram comprises its key components, including the thermostat, heaters, ventilation system, and insulated chamber, all working together to ensure even heat distribution. The diagram provides a detailed overview of a hot air oven and its components.

The outer body, which is made of metal, works as a protective shell insulated to retain heat and ensure energy efficiency and safety for the user. The inner chamber where materials are placed is located inside the outer body. The inside chamber is made of stainless steel, which is heat resistant. Stainless steel also works for durability and hygiene.

A layer of insulation is present between the outer body and the inner chamber. It prevents heat loss while maintaining temperature and conserving energy. The heating element, placed inside the chamber, generates high temperatures for sterilization and drying, producing heat that flows all over the oven.

A thermostat on the control panel allows controlled regulation of the oven's internal temperature, ensuring optimum conditions for specific tasks. The ventilation system includes an air circulation fan to circulate hot air evenly inside the chamber for even heat distribution, which eliminates temperature shifts and improves the oven's efficiency.

The oven features adjustable and removable shelves, allowing it to handle various types and sizes of materials for versatile use. Its insulated door is equipped with a gasket that creates an airtight seal, preventing heat from escaping and ensuring a stable internal temperature. The control panel outside includes switches, timers, and temperature indicators, making it easy for users to observe and adjust the oven's settings.

The temperature and time settings for a hot air oven can significantly impact the outcome of your process. For sterilization, commonly-used settings include 170°C (338°F) for 30 minutes, 160°C (320°F) for 60 minutes, and 150°C (302°F) for 150 minutes to ensure effective microbial elimination.

When drying materials, temperatures ranging from 105°C (221°F) to 120°C (248°F) are typically used, with drying times varying based on the material's moisture content and thickness.

For baking or curing, temperatures between 150°C (302°F) and 180°C (356°F) are common, with times ranging from 10 to 60 minutes. Always adjust these parameters according to the specific requirements of your application or material to achieve optimal results.

Hot air ovens generally have two types – Static hot air oven and forced hot air oven. However, for industrial purposes, Testronix offers two models – Laboratory and Digital hot air ovens. The following are the working of these two types:

A laboratory hot air oven is widely used in scientific research, pharmaceutical industries, and microbiology labs for sterilization, drying, and heat treatment of glassware in various industries. It operates by circulating heated air to ensure uniform temperature distribution, removing moisture and contaminants. These ovens are essential for maintaining sterile conditions in laboratories, making them a crucial tool for testing in the manufacturing and packaging industries.

A digital hot air oven is designed for industrial applications requiring precise temperature control, such as pharmaceutical and material testing industries. Equipped with digital temperature controllers and programmable settings, it ensures consistent heat distribution for processes like curing, annealing, and drying of materials. Its advanced features improve efficiency, reduce energy consumption, and enhance reliability, making it ideal for modern industrial and research environments.

| Feature | Autoclave | Hot Air Oven |

| Sterilization Method | Uses moist heat (pressurized steam) | Uses dry heat (hot air circulation) |

| Operating Temperature | Typically, 121°C to 134°C | Typically, 160°C to 180°C |

| Sterilization Time | Shorter (usually 15-30 minutes at 121°C) | Longer (usually 1.5-2 hours at 160°C) |

| Pressure Requirement | Requires high pressure (15 psi or more) | Operates at atmospheric pressure |

| Suitable Materials | Ideal for liquids, culture media, surgical tools | Ideal for glassware, metal instruments, powders |

| Unsuitable For | Items sensitive to moisture or pressure (e.g., powders) | Items sensitive to high dry heat (e.g., rubber, plastics) |

| Efficiency | More effective in killing spores and microbes quickly | Less efficient; requires higher temperature and time |

| Application Areas | Hospitals, biotech labs, pharmaceutical sterilization | Research labs, microbiology labs, material testing labs |

| Energy Consumption | Generally lower due to faster cycle | Generally higher due to longer operation time |

| Cost | Usually more expensive to purchase and maintain | Usually less expensive and simpler to operate |

A hot air oven is a perfectly-engineered lab testing instrument designed to condition the specimen for various testing dynamics and also assess the ability of various materials to withstand elevated temperatures when exposed to the environment. The Hot Air Oven simulates real-life atmosphere around the specimen to determine the reactions of the specimen. The working of the instrument is a followed:

When it comes to working with chemicals and other materials in a laboratory setting, safety is always the top priority. One of the ways that laboratories ensure safety is by using hot air ovens. Hot air ovens are enclosed chambers that use hot air to sterilize equipment and supplies.

There are several benefits of using a hot air oven in a laboratory setting.

Overall, the use of hot air ovens in laboratories provides many benefits that help to keep laboratories safe places to work.

Hot air ovens are one of the most common pieces of equipment found in laboratories. They are used for a variety of tasks, such as drying glassware, heating up chemicals, and sterilizing equipment. While they may seem simple to use, there are a few things to keep in mind when using a hot air oven in a laboratory setting.

Once the oven is turned on, it will take some time for it to reach the desired temperature. When it does, you can begin your work. Remember to always wear protective clothing when working with hot materials, as they can cause burns if you are not careful. Once you are finished using the hot air oven, be sure to turn it off and allow it to cool down before opening the door. You can read more on the significance of hot air oven in testing laboratory.

When using a hot air oven in a laboratory, there are several precautions that should be taken in order to ensure safety.

Hot air ovens are incredibly useful pieces of equipment used in laboratories, offering efficient and reliable heating for a variety of purposes. Their ability to reach high temperatures without damaging the material being heated makes them ideal for sterilizing laboratory materials as well as conducting other experiments. With their easy-to-use controls and uniform heat distribution, hot air ovens offer a versatile solution for any laboratory - spend time researching which model is best suited to your needs today. Contact us today to learn more about the best quality Hot Air Ovens in India.

A hot air oven is used for dry heat sterilization, drying glassware, removing moisture from samples, and testing the heat resistance of materials in laboratories. It is commonly used in microbiology, pharmaceuticals, and research labs to sterilize items. In general, it utilizes dry heat to kill microorganisms, bacteria, and their spores, ensuring the safety and hygiene of equipment and materials.

A hot air oven can sterilize heat-resistant materials such as glassware (like test tubes, Petri dishes, and flasks), metal instruments, forceps, scalpels, and dry powders. It is also suitable for sterilizing oils, greases, and other substances that cannot be sterilized using moist heat or steam. However, it is not recommended for materials like plastic, rubber, or liquids.

The temperature and time for a hot air oven can vary based on the procedure. For sterilization, general settings are 170 degrees Celsius for 30 minutes, 160 degrees Celsius for 60 minutes, or 150 degrees Celsius for 150 minutes to eliminate microbes.

Drying generally requires 105 degrees to 120 degrees Celsius, with times depending on moisture and thickness of the material. Baking or curing uses 150 degrees Celsius to 180 degrees Celsius for 10 to 60 minutes.

The principle of a hot air oven is based on dry heat sterilization, which eliminates microorganisms using high temperatures. The heat circulates within the chamber, starting from the surface of the material and penetrating to its core. A PID controller regulates the heating process, ensuring accurate temperature control for effective sterilization.

The Hot air oven sterilization procedure uses dry heat to kill microorganisms on materials such as glassware, powders, oils, and metals. Clean items and place them in the oven. Sterilized at temperatures 170 degrees Celsius for 30 minutes or 160 degrees Celsius for 60 minutes. When the cycle is complete, the oven will cool down, then remove the items for safe use.

A hot air oven is an equipment that can be used for drying, heating, sterilizing, and curing materials. It circulates hot air inside an insulated chamber while controlling temperature for even heating. Many industries, like pharmaceuticals, food processing, and laboratories use hot air ovens to sterilize equipment.

Applications of hot air ovens are more than you can think of. Here are applications of hot air oven:

In laboratories, hot air ovens are used for different purposes, such as drying glassware, heating materials, and sterilizing equipments. Take these precautions to use hot air ovens in laboratories: