Reviewed by Anurag Mishra (Sr. Technical Consultant)

The mainstream of the packaging world has always been very focused on the safety and integrity of products. However, undetected leaks, damages caused to products, customer complaints, and losses on a financial level plague manufacturers and have always been a part of their worries. For a long time, the packaging industry needed reliable solutions for this problem, and vacuum leak testers became an unsung hero. But how exactly do they help and why should packaging industrialists invest in this technology?

Packaging defects are generally unnoticed during production time as minuscule leaks are not really observable to the naked eye. Leaks can actually degrade product quality while causing an increase in spoilage, and eventually, it can become a matter to be used against the reputation of the brand. Whether it is food, medicine, or consumer products, a leaking package is not something a manufacturer can afford to overlook. What will emerge then is costly recalls and whining customers. What's the answer?

Vacuum leak testers are among the fantastic instruments that can detect even the minutest leakages in packaging. These instruments quite accurately determine whether a package is airtight or not by simulating realistic pressure conditions. Vacuum leak testers help the manufacturers determine the leakage even before they reach the consumer, hence only defect-free packaging will go out of the production line, which will prevent costlier returns from the consumers while enhancing customer trust and satisfaction.

You might be thinking: Why should you choose Testronix? With more than 11 years of high-quality manufacturing experience in testing instruments, Testronix has come to hold a leadership position in the testing industry of packaging. It is excellence in what we do, attracting some of the high-profile clients in the pharmaceutical sector, food packaging, and FMCG.

Not only does Testronix's vacuum leak tester stand tall in terms of accuracy but also by its durability and friendliness to the user. We pride ourselves on cutting-edge technology that meets international standards while ensuring ease of use for the user.

However, our leak detection knowledge is only part of our broader portfolio. We address the demand for fully integrated test tools for packaging designed to simplify quality control at every point in the manufacturing process. With Testronix, you are selecting a trusted industry leader - one to which global brand names turn to safeguard their products.

And here's the numbers game:

Beyond the confidence of product integrity, Testronix vacuum leak testers also bring about large cost savings for manufacturers. Here's how.

However, these advantages do not work on theoretical grounds, they have been fact-checked with first-person case studies of manufacturers who have benefited from vacuum leak testers made by Testronix.

Vacuum leak testing is accurate enough that it's applied not only on packing but even in the aerospace field for testing important parts. That's the precision you're committing to when you select a Testronix vacuum leak tester.

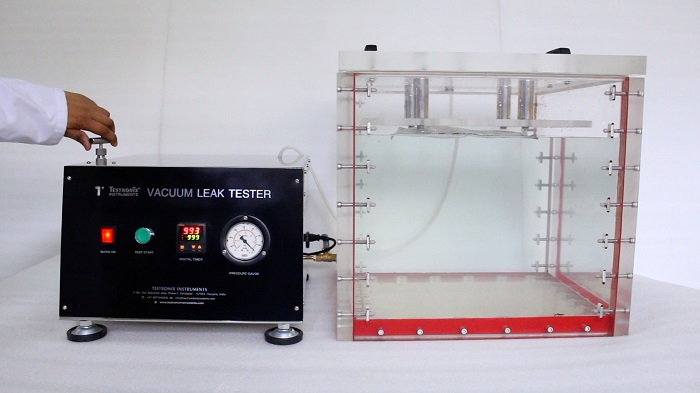

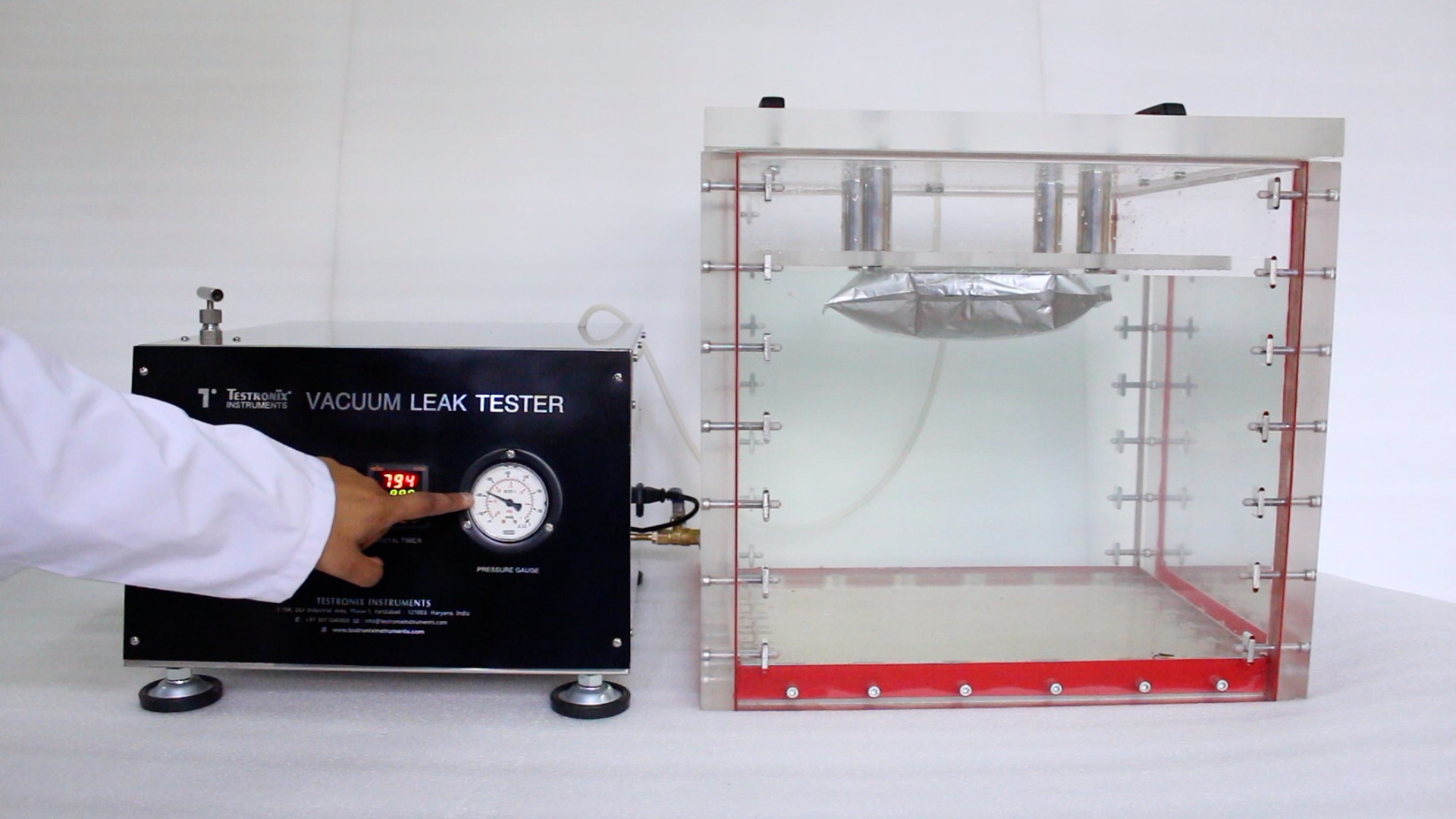

A vacuum leak tester is an apparatus in which a package is put in an airtight enclosure. Vacuum pressure is then applied to the package. If there is some leakage involved, the packaging would deform and indicate that indeed there is a defect.

To this day, vacuum leak testers may be used on packaging materials like plastic bottles, sachets, cartons, and even more. There is no size limit, neither in the material.

It is important to calibrate from time to time, especially for accuracy. According to Testronix, the tester must be calibrated from every 6 to 12 months depending on usage.

With a vacuum leak tester from Testronix, you improve your quality control, as well as your brand's reputation reduce cost, and optimize production efficiency in an industry where everything counts. Testronix offers the superiority of precision and reliability that modern manufacturers require.

Ready to go to the next step in packaging quality assurance? Contact us today to learn more about what vacuum leak testers by Testronix can do for your production line and ensure high-quality leak-free packaging. Let's secure your success, one test at a time.

Phone: +91 9313 140 140

Email: info@testronixinstruments.com