Reviewed by Anurag Mishra (Sr. Technical Consultant)

Many industries- such as textiles, plastics, coatings, and packaging- require color consistency, because the color of a product not only denotes aesthetic appeal but also represents the identity of a brand and consumer satisfaction. For manufacturers, it is important that the color comes through consistently for each production batch so that brands are recognized, customer expectations are met, and their products look right and uniform.

Hence, in relation to color constancy, especially in terms of appearance and color matching, widely available standards like ASTM D1729 are used. It is a systematic approach for color constancy assessment carried out under-regulated lighting. To meet this imperative for any company, Testronix presents highly advanced color measurement instruments to ensure that manufacturers match color accurately and be consistent with it while improving processes and elevating product quality.

ASTM D1729 is a published standard detailing the visual examination of color uniformity, specifically in terms of the appearance of the product under different lighting conditions. The standard describes the steps necessary for the evaluation of uniformity of color in materials and products, with emphasis on the simulation of real-life lighting situations such as daylight, interior illumination, and retail display.

The objectives of ASTM D1729 are to present some controlled environments that test the degradation behavior of the color of a product against several types of light sources. The manufacturers can visually compare the color of the product against the particular lamp conditions of D65, simulating daylight, and A, as well as F-11, retail store lighting, but this does not comply with the requirements of specifications.

Testronix is one of the quality testing equipment manufacturers that provide accurate and quality testing equipment designed for specific markets such as packaging and plastics. The company follows international standards, like ASTM and ISO, to ensure accuracy and the repeatability of tests.

The company's instruments are designed with user interfaces and built using heavy-duty materials to make them last, making Testronix one of the primary choices for quality control.

Color consistency often proves difficult to achieve in production runs due to various factors that cause color variation. They include:

The worst that comes out from color inconsistency is the rejections of the product, which could be costly; unhappy customers and increasing production at a very high cost. Without any standard for color evaluation, such problems lead to reduced quality and reputation for your brand.

ASTM D1729 helps manufacturers with a standardized procedure for color evaluation to overcome such problems. This approach ensures color consistency in many ways:

The ASTM D1729 test procedure is not exactly intricate but demands careful attention in its implementation to produce proper results:

Pretest: Manufacturers first prepare the test specimens and arrange lighting conditions as specified by the standard.

Observation: The test samples are observed under prescribed lighting conditions for visual appearance.

Evaluation: The color of the samples is then evaluated either by a color-matching system or visually.

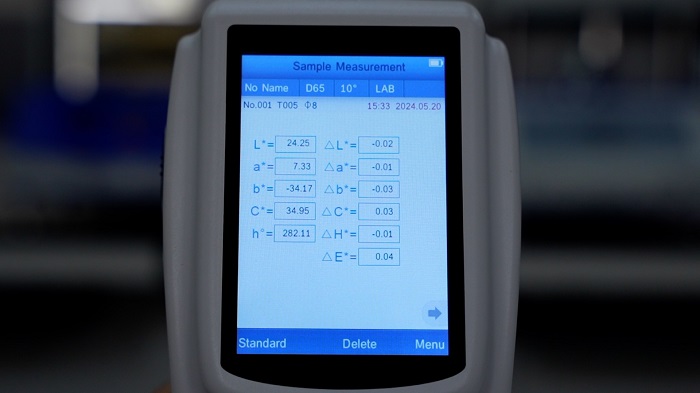

Even though visual tests are important, colorimeters or spectrophotometers allow one to obtain objective, numerical values that can be used to accompany the visual tests.

Using ASTM D1729 testing procedures has many advantages to the manufacturer:

ASTM D1729 is a standard method used for the determination of the color consistency of a sample under controlled illuminating conditions. This is important because it will make it possible for a manufacturer to ensure its product leaves the factory consistent, and color specifications are achieved, which improves the quality of the product and satisfies the consumer.

ASTM D1729 testing must be performed regularly, especially in the case of new materials and production settings change or in the concern of batch-to-batch consistency.

Yes, ASTM D1729 can be used on many kinds of products, which include textiles, plastics, paints, as well as packaging, to determine colorfastness under a variety of lighting conditions.

Connect with us today. Testronix’s experts will help you to achieve your quality goals.

Phone: +91 9313 140 140