Reviewed by Anurag Mishra (Sr. Technical Consultant)

The pouches are used for the packaging of sensitive, eatables, and daily usage products like soaps, washing detergents, snacks, etc. These packaging materials are used to enhance the safety of products and prevent them to get contaminates or compromised in case of exposure or accidents.

For example, there are washing detergents & cleaning materials like naphthalene that have a tendency to evaporate in the case of exposure to the environment. To avoid such issues, the pouches are used as a protective layer over these items & products. However, there are instances of leakages in the case of faulty integration of these seal pouches. Understanding with another example, sachets containing shampoos sometimes get leaked which happens due to faulty or weak integration or poor sealing of the pouches.

Therefore, it is necessary for manufacturers to assess the quality of these pouches before utilizing them in the final production procedure. Manufacturers undergo various testing measures to ensure the quality of these packaging materials.

The Leading lab testing manufacturer in the country - Testronix has come up with a technically advanced lab testing instrument called the vacuum leak tester for pouches that aids manufacturers in identifying the leakages in pouches (if any) which provides a sense of assurance to not just manufacturers but also consumers who buy the product.

The lab testing equipment is structured ergonomically with an easy working schedule that allows the operator of the instrument to get familiar with the device quickly and perform testing seamlessly without any problem at all.

The instrument is designed with extreme precision to determine the leakages in a pouch used for the packaging of various products.

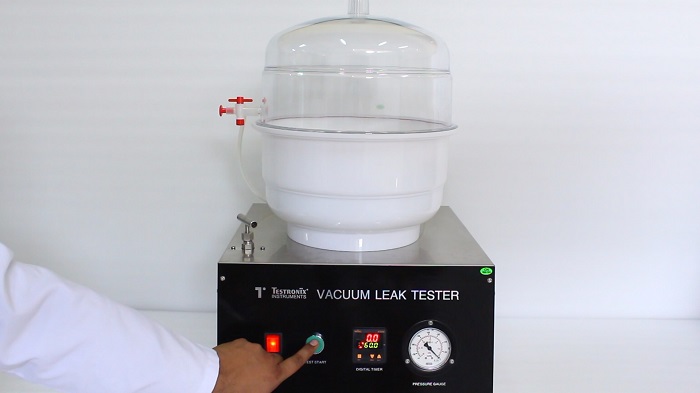

The first and foremost step to initiate the leakage test with the pouch vacuum leak tester is to place the specimen in the testing chamber. The vacuum leak chamber size can vary from 150 mm to 300 mm as per the requirement of the consumer or the operator, adhering to the size of the specimen.

The operator must close the vacuum leak chamber lid firmly after placing the specimen to ensure 100% insulation inside the chamber of the vacuum leak tester.

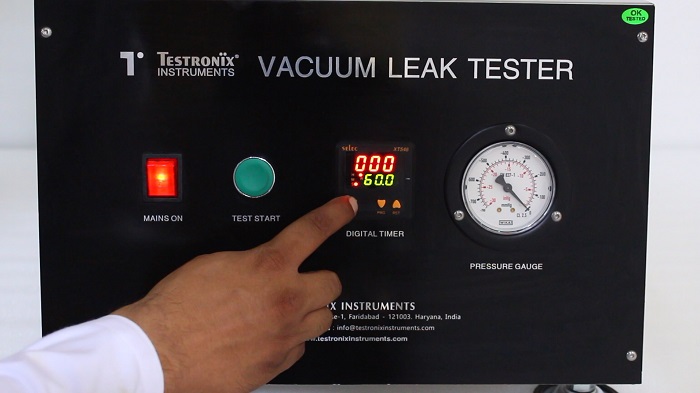

The operator can now adjust the run time of the instrument with the help of the preset timer associated with the control panel of the instrument.

The operator can exert the air pressure into the chamber with the help of the rotating valve attached to the instrument. The pressure exerted can be seen on the air pressure gauge.

The air pressure exerted into the chamber forms a vacuum inside the walls of the specimen which results in the exertion of pressure on its walls from the inside hence, in the case of a leakage the vacuum leaks out, and the operator is informed about the uncertainty due to the transparent build of the testing chamber. Instances where the pouch is carrying a fluid inside it result in the leakage of fluid itself from the leakage.

This is how manufacturers determine the seal integrity & identify leakages (if any) in the specimen.

The instrument is trusted by manufacturers all across the globe due to certain high-end features that it carries. It is important to take a look at these features and identify the specialty of the pouch vacuum leak tester.

The vacuum leak tester manufacturer has imbibed the instrument with top-notch quality characteristics that not only aid manufacturers with accuracy but also ensure a seamless testing experience for operators.

One of the most attractive features of the instrument is the incorporation of a pressure gauge along with the rotating pressure valve that allows the operator to keep a check on the amount of pressure being exerted along with an easy exertion process that promotes single-handed testing measures.

The vacuum leak tester is also offered with a transparent or see-through vacuum leak testing chamber that also allows the operator to keep an eye on the specimen at all stages during the course of testing.

The instrument is equipped with an advanced preset timer that enables the operator to conduct testing as per the designated time and also comply with all the necessary standards.

The vacuum leak tester manufacturer offers the instrument in two variants which differ in the size of the testing chamber i.e. 150 mm & 300 mm, allowing the operator or manufacturer to test even the bigger specimens with absolute facile.

All these features accumulate together as a pack of high-quality characteristics to gain the trust of manufacturers by ensuring quality and elevating testing standards.

The pouch vacuum leak tester is designed with an amazing engineering standard followed by the leading manufacturing company – Testronix. To determine & indicate the leakages in pouches you can get a vacuum leak tester for pouches. To place an order or book the instrument for yourself, you can simply contact us by calling us at +91 9313140140 or writing to us via e-mail at info@testronixinstruments.com. We will be extremely happy to serve you the quality you deserve.