The Testronix Dart Impact Tester assesses how a plastic film withstands the impact of a falling dart. The energy from the falling dart induces failure in the film under controlled conditions. The dart, featuring a hemispherical head, is securely held by an electromagnetic holder and released with a button press. The heights from which the dart is dropped can be adjusted as needed.

It evaluates the impact resistance of plastic films. It promotes precise and accurate results. There are many packaging industries, especially, where this quality comes in handy, and determines the quality of the end product.

The Testronix Dart Impact Tester is an instrument that imitates the effect (sudden) of the free-falling dart. This helps in understanding the durability of the product when it is handled in further stages of production or post.

FEATURES:

- The dart is held before release and it ensures consistent positioning.

- Height Adjustment Mechanism: This judges the height from which the dart is to be dropped. It enables imitation of various real-world scenarios.

- Control Panel: equipped with buttons for interface use

USES:

The Dart Drop Impact Tester finds applications across multiple industries:

- Packaging - Protection of the packaging and the product lies on this ability/property. Their safety can be assured.

- Manufacturing - Electronics or Automotives, especially, need to be durable in terms of their plastic components.

- Quality - Quality standards can be adhered to and your quality team can have a hassle-free job.

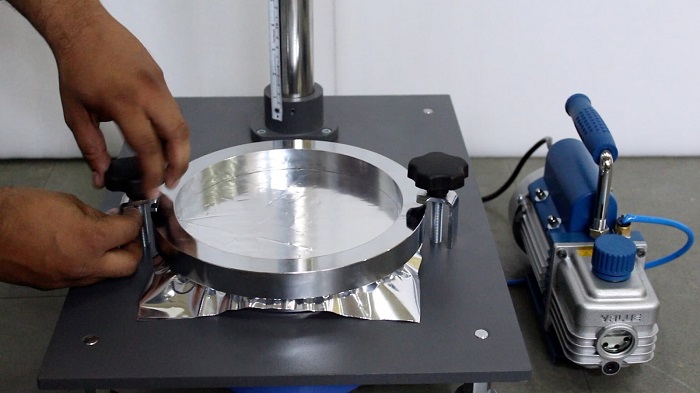

HOW TO CALIBRATE:

If you regularly calibrate the device, it produces accurate and consistent results.

- Clean the dart inspect it for any irregularity and confirm if the electromagnetic holder is working properly.

- Check if the height is set properly and it is at a proper position to ensure a suitable height for the dart to drop from.

- If your load cell measures impact force, calibrate it according to the manufacturer's instructions using calibrated weights.

- Ensure the working of the interface where results are displayed.

- Regular cleaning and maintenance are helpful.

BENEFITS:

The Testronix Dart Tester is very critical in material testing:

- Imitates actual conditions of drop tests so that the material is put to realistic tests.

- Products meet quality standards and will ensure zero rejection in the post-production process. It reduces the costs of failures.

- The quantitative data on materials can be used to design products and fine-tune it.

- Quality standards can be adhered to, especially in the case of packaging materials.

FAQS:

Q) What materials can the falling dart impact tester test?

A: It is mainly used to assess the impact resistance concerning plastics - films/sheets. It tests their ability to face sudden impacts like that of the dart itself - and the consequent effect on the testing material.

MATERIALS OF TESTING:

- PLASTICS: Most plastics are assessed for their resistance to impact upon dart falling.

- Polyethylene (PE), polyvinyl chloride (PVC), etc are used often. The findings assist assess if these materials are suitable for protecting products during shipping and storage.

- The Dart Impact Tester can also test some types of stiff polymers, such as those used in consumer electronics or automobile components, with specific fixtures and adapters. certain tests determine how well certain materials can endure impacts without breaking or fracturing.

- Composite items: In some circumstances, composite materials containing plastic components can be examined. These tests serve to determine how different layers or components of the composite construction contribute to total impact resistance.

Q: Can it be used for research?

A: Yes, researchers frequently utilize the tester to investigate material behavior under impact, which contributes to advances in material science and engineering.

However, beyond their traditional role in quality assurance, dart impact testers offer compelling advantages in research.

In research settings, these testers provide controlled and repeatable conditions for studying how materials behave under specific stressors. This includes exploring fracture mechanics, energy absorption properties, and failure modes crucial for advancing material science. Moreover, dart impact tests can be customized to simulate varying impact angles, velocities, and temperatures, making them a versatile tool for investigating material performance in diverse environments.

Additionally, dart impact testers facilitate comparative studies across different materials or formulations, supporting the optimization of material properties tailored to specific applications. Researchers can use these tests to evaluate the impact resistance implications of changes in material composition or manufacturing processes, yielding valuable insights for both industry and scientific advancement.

Nevertheless, utilizing dart impact testers for research poses challenges, particularly in adapting standardized testing protocols to suit unique experimental requirements. Furthermore, analyzing complex impact data demands advanced techniques and a deep understanding of material responses under dynamic loading conditions.

In summary, while dart impact testers are primarily utilized in industry to ensure product quality, their ability to offer controlled impact conditions and flexibility in testing parameters makes them equally valuable for scientific research. By harnessing these capabilities, researchers can deepen their comprehension of material behaviors and drive innovations across various sectors. Thus, dart impact testers represent a potent tool not only for industrial applications but also for expanding scientific knowledge in the field of material science.

Want to know the dart impact tester price? Reach out to us through a phone call at +91 9313 140 140 or directly dropping us an e-mail at info@testronixinstruments.com.