Reviewed by Anurag Mishra (Sr. Technical Consultant)

This blog gives an overview of dry heat sterilization that details its definition, instruments, principles, benefits, formulas, limitations, and factors affecting efficiency. Also, it's a comparison with some other methods and FAQs on the topic for better enlightenment.

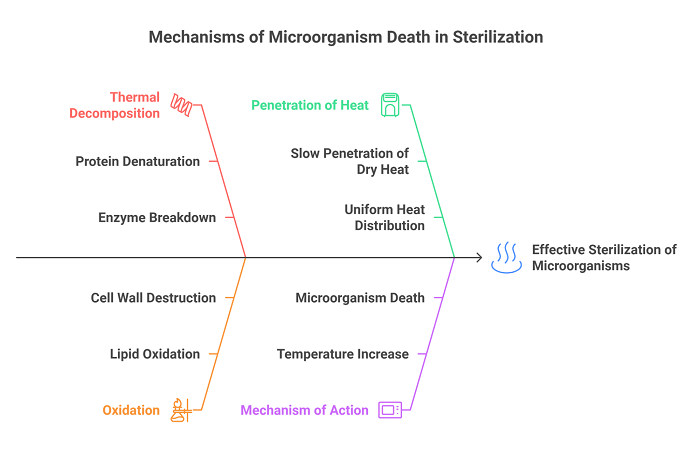

It involves the application of high temperatures to materials to sterilize. The principal mechanism involved is thermal decomposition whereby the proteins and enzymes of the microorganisms get denatured and consequently killed by structural disintegration. Since this process doesn't involve moisture, it is quite appropriate for the application in cases of those items that are heat-stable but moisture-sensitive, just like autoclaving (steam sterilization). This method does not need moisture, thus is suitable for those items that are heat stable but moisture sensitive just like autoclaving or steam sterilization.

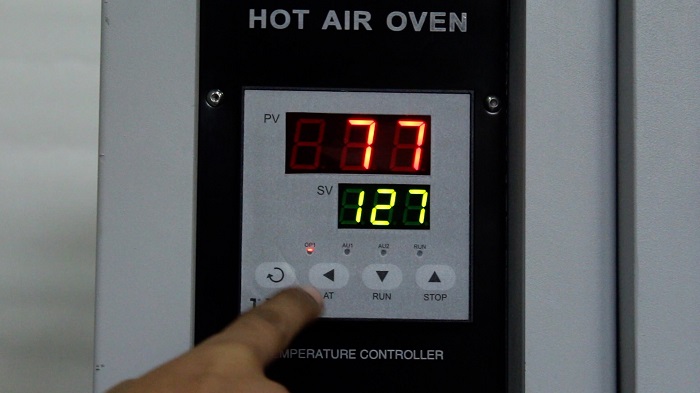

The range of temperatures between 160-180°C (320-356°F) should be applied in dry heat sterilization. The possible exposure time varies from about 1 to 2 hours, depending on whether the material is to withstand slight or high sterility degradation. Dry heat sterilizations prefer all materials that are prone to degradation or corrosion when it comes to steam or another moist heat method. For instance, glass, metallic, powders, or oils.

The device used to achieve dry heat sterilization is referred to as the dry heat sterilizer, or dry heat oven. Dry sterilizers are devices that rely on high temperatures to destroy, thereby making materials sterile by eliminating microorganisms through heat in dry conditions. They are used to perform the sterilization of glassware, metal equipment, powders, and other certain chemicals that can be damaged during the process due to wet conditions.

No Moisture Damage: Dry heat sterilization best suits materials sensitive to moisture including various metals like surgical instruments as well as powders or oils.

Long Shelf Life: Since dry heat sterilization can easily preserve the quality of those materials that might degrade in steam or moist heat, items sterilized this way often have a much longer shelf life.

No Rusting: Unlike moist and steam sterilization where one is likely to develop rust and corrosion on most metals, dry heat does not introduce moisture. Thus, the longevity of metal instruments remains intact.

Inexpensive: The dry heat sterilization method would also be economically beneficial since nothing except the sterilization device would be required. Effective Microbial Destruction: Dry heat Sterilization annihilates many microorganisms (typically bacteria, viruses, and fungi spores).

Dry heat sterilization is not the most suitable option for all types of materials. Significant differences are observed in the comparison of dry heat sterilization with other sterilization methods like autoclave, ethylene oxide, and radiation sterilization.

Autoclaving: The ideal method of sterilization for the majority of items is steam sterilization (Autoclaving) because it uses moist heat but might destroy heat-sensitive materials or corrode the metals. The dry heat sterilization process is preferred when moisture is adverse.

Ethylene Oxide Sterilization: The process here requires the use of a gas for the process. However, because the gas is toxic, long exposure times and careful handling are required.

Radiation sterilization: This is practicable for only a few medical devices and pharmaceuticals but it is relatively expensive as well as highly technological equipment.

Longer Process: Typically, it is slower in comparison to the wet methods of sterilization and consumes processing time and energy as well.

High Energy Consumption: It consumes high amounts of energy and requires high temperatures over more extended periods.

Fewer Materials Compatibility: Dry heat methods are not applicable on items that are heat-sensitive like plastics, rubber, or a particular type of electronics.

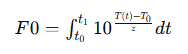

The F0 is the value used to evaluate the efficiency of dry heat sterilization, a formula or measure to consider both time and temperature for its process. This formula is:

Where:

FAQs

Dry heat is well suited for glass, metal, powders, oils, and other things that cannot stand moisture.

Typically, dry heat is around 1 to 2 hours depending on the type of material and temperature.

Yes. This is because dry heat takes a lot of time to exposure at very high temperatures.

Want to find out more about dry heat sterilization and how it can benefit your processes? Check out our comprehensive guide for insights on its principles, and benefits, among others. Contact us now for expert advice and tailor-made solutions for your particular needs!