There are different types of materials that are used in the production process of all the products that are used by people to make their lives easier. However, manufacturers are the thankless heroes that undergo extremely rigorous manufacturing, packaging, shipment, and other measures to serve a good quality product.

One aspect of manufacturing products with extreme precision is to segregate the correct raw materials from the ones with poor quality as these products have extremely high versatility and are used in different fields. Manufacturers measure the quality of these raw materials by conducting various tests but one of the most important tests is to ascertain the reactions in their constantly changing properties under variable & extreme climatic conditions as these products are exported worldwide and experience diverse atmospheres in different hemispheres.

To aid manufacturers in assessing the reactions in mechanical properties, the leading lab testing instrument manufacturer in the country – Testronix has come up with a UV weathering chamber.

You might have observed the faded color stains on plastic chairs or faded color of clothes and hampered textile quality due to overexposure to sunlight under a certain climatic condition. The instrument simulates such weathering conditions and evaluates how different materials react to variable environments when exposed to nature.

The UV weathering chamber functions various items all at once but still offers an ergonomic working structure for the operator of the instrument to ensure the cyclic testing measures expeditiously.

Working Structure of the UV Weathering Chamber

The UV weathering testing machine is offered with a facile testing methodology with cyclic testing that allows the operator to conduct testing as per the requirement and critically examine the quality of the raw material.

The raw material is placed in the sample holder tray and is locked with the O-type locking mechanism. The operator must make sure that the front of the specimen faces the UV lights integrated next to the specimen holder tray.

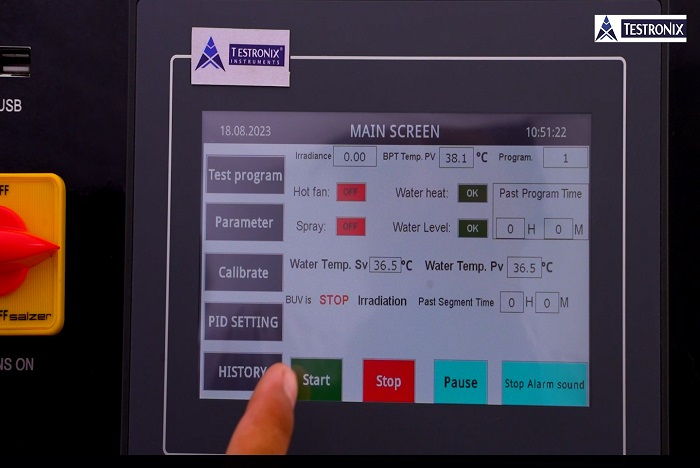

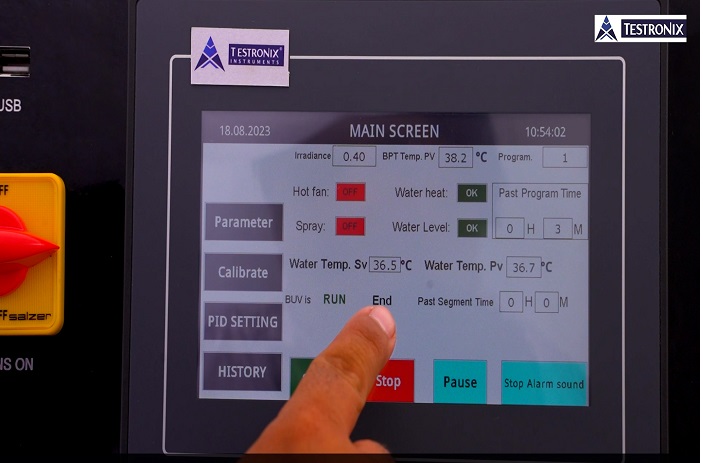

The operator can adjust the timings of the test with the help of the LCD touchscreen associated with the outside of the UV weathering testing machine.

The machine first performs the dry testing measure where the UV lights interact with the surface of the specimen under extremely hot and dry weathering conditions. The instrument is equipped with SSR-based heaters that elevate the temperature inside the inner testing chamber.

The UV weathering test chamber follows the second cyclic method of humid weathering conditions when the UV light interacts with the specimen’s surface. The humid conditions are simulated with the help of sprinklers integrated into the walls of the inner chamber. The instrument is offered with a reservoir tank that carries the water supply for the conduction of humid & rainy weather simulation tests.

The final methodology in the functioning of the UV weathering test chamber is condensation where the extreme cold climate is simulated. The process takes place with the help of the air conditioners included in the testing chamber. The UV lights react with the surface of the specimen under extreme cold climates as the air conditioners lower the temperature inside the testing chamber.

The same testing methodologies are repeated for an adjusted time and numerous times as adjusted by the operator. The constant cycling testing mode of the instrument exposes all the reactions of the properties of the material being tested and allows the operator to segregate the material as per the requirement.

The operator can also record the data used in the testing measures using the HMI-based touchscreen. All these testing methodologies are possible due to the high-end & advanced features incorporated within the instrument to make the instrument a precise imitator of certain weathering conditions along with the spread of UV light rays.

High-End Features of the UV Weathering Chamber

The UV weathering chamber manufacturer promises top-notch features within the instrument that not only expedite the testing process but also elevate the testing experience of the operators.

The first & foremost feature of the instrument is the incorporation of 16 sample-holding trays that enable the operator to conduct the test on 16 different material types all at once. The sample positioning tray is also offered with an O-type locking mechanism that ensures the precise positioning of the specimen.

The specimen is offered with 1) heaters for elevating the temperatures inside the testing chamber and performing the dry heating methodology; 2) Reservoir tank & sprinklers for carrying the water supply and spreading it across the specimen for simulating humid & rainy climate conditions; 3) air conditioners for performing the final methodology of the cyclic test which is called the condensation that simulates extreme cold environment.

The instrument is also offered with 3 different light assemblies for simulating the UV light interaction with the surface of the specimen attached to the rotary panels of the specimen holding tray.

The testing standards are elevated to a higher notch by the installation of the HMI-based touchscreen that allows the operator to perform the test with absolute facile and promotes single-handed testing by the manufacturer of the specimen or the operator of the instrument.

The instrument is also incorporated with two German-made aerodynamically advanced fans that are operated through a toggle switch associated with the control panel. These fans ensure that the controlled atmosphere inside the testing chamber is uniformly distributed all across the specimen holder for precise test results.

The UV weathering chamber manufacturer has used stainless steel as the primary material in the construction of the instrument to ensure anti-rusting qualities and long-term durability of the device.

Get the Revolutionary UV Weathering Chamber ASAP

To evaluate the properties of various materials against UV rays under certain circumstances in a cyclic manner, you can get your hands on the top-notch UV weathering chamber right away. To know more about the specs & details of the instrument, visit our website without any further delay.

Give us a call straight away to place the order for the high-end instrument at +91 9313140140 or e-mail us at info@testronixinstrument.com.