Reviewed by Anurag Mishra (Sr. Technical Consultant)

Packaging pouches are widely used in different industries to deliver and store products accurately. Thus, testing each and every aspect of the vacuum is an important aspect of quality control. Ensuring that pouches are free from any vacuum leaks is of utmost importance as it guarantees the preservation and integrity of the contained materials. The consequences of neglecting this crucial step can be severe, potentially compromising product quality, and shelf life, and even causing harm to end-users.

With our vacuum leak tester, manufacturers of the paper and packaging industry can easily test their pouches for vacuum leaks. This testing instrument creates vacuum pressure to test the vacuum leak integrity of the materials with ease.

In this blog, we will focus on how you can easily conduct vacuum leak tests on pouches with the help of our high-quality lab testing instrument.

Vacuum leaks in pouches often pose a common challenge for packaging manufacturers and packagers, resulting in frustration and the risk of product spoilage or contamination. But what precisely constitutes a vacuum leak, and what leads to its occurrence? In this section, we aim to introduce vacuum leaks in pouches, shedding light on their causes and potential repercussions.

To start, let's establish the concept of a vacuum leak. A vacuum leak occurs when air or gas infiltrates a sealed package that should ideally maintain a controlled level of negative pressure or vacuum.

Using an accurate vacuum leak tester for the packaging industry will help manufacturers ensure the accurate integrity of products.

With the use of this high-quality lab testing instrument designed by the experts at Testronix, manufacturers can easily conduct vacuum leak tests. You can also read more on the important factors to consider in increasing the shelf-life of materials using a vacuum leak tester.

When it comes to ensuring the quality and integrity of vacuum-sealed pouches, the importance of detecting and reducing vacuum leaks cannot be overstated. By using high-quality vacuum leak testing machines, manufacturers can easily ensure that their products remain safe during transportation and storage.

Pouches are often made from thin plastic layers that can easily tear or puncture during handling or transportation. Even small holes or tears can create enough space for air molecules to enter the package over time. With vacuum leak testing instruments, manufacturers can reduce the leaks present in the pouches and deliver accurate products.

Now, let us discuss the top features of a vacuum leak tester designed by the experts at Testronix.

If you make the use of vacuum leak tester eco digital model, then you will get high-quality features that are written below:

Now, let us discuss how you can operate a vacuum leak tester.

To operate the vacuum leak tester, you can follow the steps mentioned below:

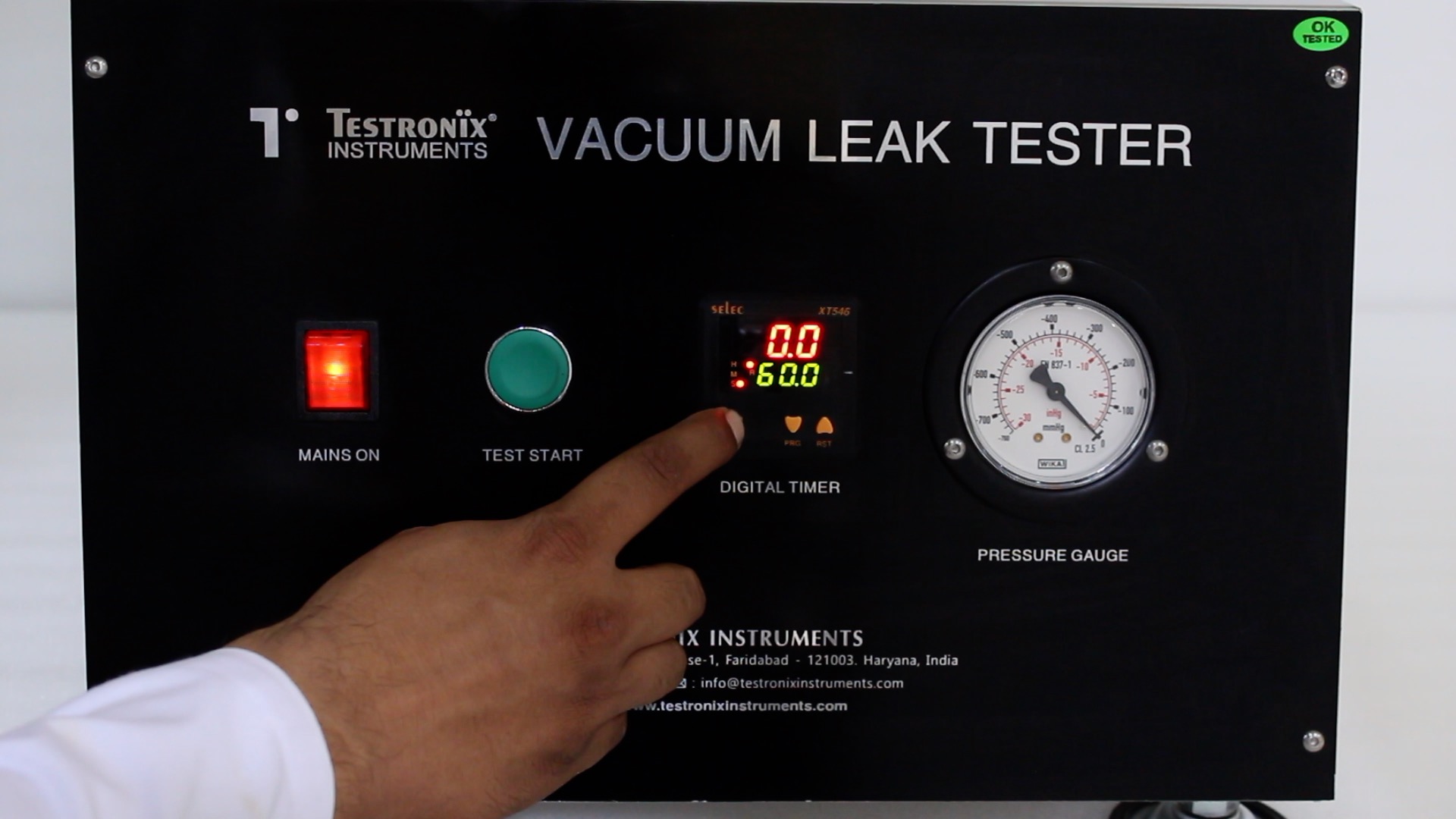

To initiate the machine, begin by plugging the mains socket into a 3-pin 15-amp outlet.

Configure the test duration on the digital timer.

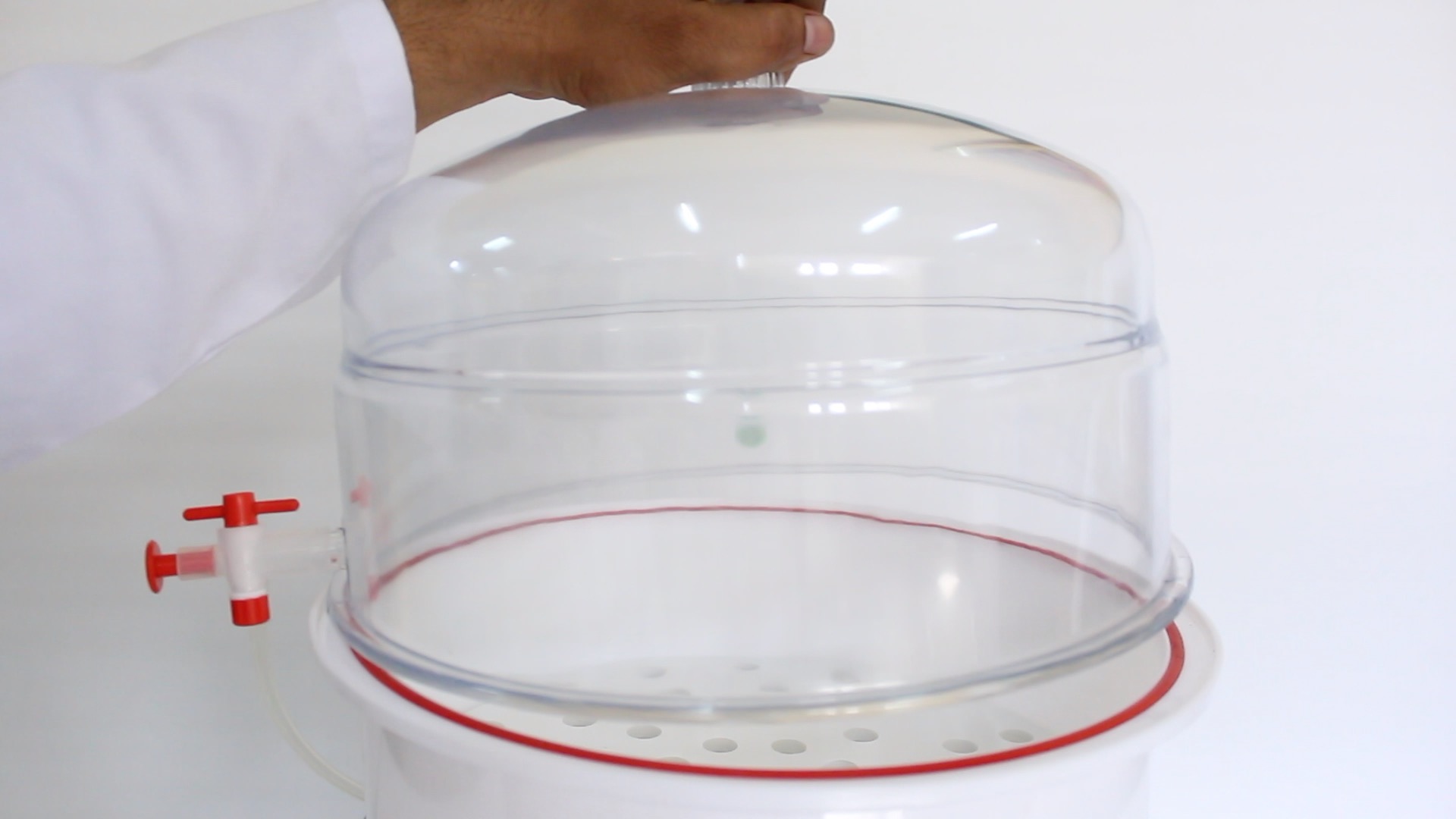

Once the digital timer is set, open the desiccator cover and position the test specimen inside.

After inserting the specimen, securely reseal the desiccator with the cover, ensuring a proper seal on the gasket. A secure seal is vital for creating a vacuum within the desiccator.

Once these steps are completed, you may proceed with the test.

In this way, you can easily conduct a vacuum leak test on the materials. If you want more information about this testing instrument then give us a call at +91 9313 140 140 or email us at info@testronixinstruments.com. Our team of technical experts will consult you regarding all your needs and queries.