What is Universal Testing Machine (UTM)?

A Universal Testing Machine (UTM) is a vital piece of equipment used to test the mechanical properties of materials by applying controlled stress, such as tension, compression, and shear forces. It evaluates material properties like strength, elasticity, and ductility. The machine typically consists of a rigid frame, a load cell for measuring force, a crosshead that applies the load, and grips to secure the specimen. UTMs come in different types, such as hydraulic, electromechanical, or servohydraulic, depending on the force control mechanism used. They are employed in a range of tests, including tensile, compressive, flexural, and fatigue testing, to assess how materials perform under different conditions.

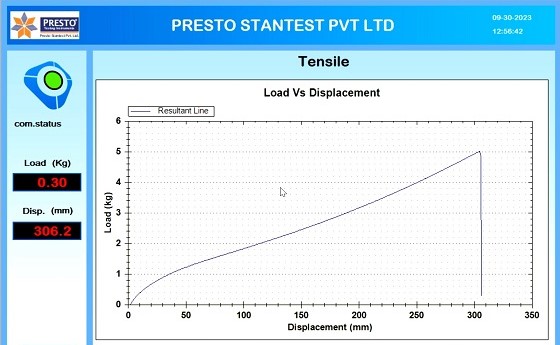

The data generated by these tests, often presented as stress-strain curves, offer critical insights into material behavior. This information is essential for applications in material development, quality control, and failure analysis. UTMs are widely used across industries such as manufacturing, construction, aerospace, and research to ensure materials meet required safety and performance standards. Their role in testing and validating materials is indispensable, helping companies create stronger, safer, and more efficient products.

Still, trying to meet the industry standards? Do you feel your resources are being wasted or can be better spent? Concerning much? Don’t worry! We’ve crafted an optimal solution for you. Acquainting you to the UNIVERSAL TESTING MACHINE (UTM). Let’s explore the instrument further and learn about its capabilities.

The word “universal” refers to the ability of an instrument to conduct multiple tests on the same apparatus. This machine is aptly named on various grounds because it is designed to perform a huge variety of tests on various kinds of materials, making it truly universal.

Universal Testing Machine (UTM) Working Principle

Universal Testing Machine (UTM) working principle is based on applying a controlled load to a test specimen and measuring its response. The UTM uses a load cell to apply tensile or compressive force and an extensometer to record deformation. This helps determine key material properties such as strength, elasticity, yield point, and ductility.

The Universal Testing Machine (UTM) Working Principle Explains:

- Applies controlled tensile or compressive force to a material

- Uses a load cell to measure applied force accurately

- Uses an extensometer to measure material deformation

- Plots stress-strain data for analysis

- Determines properties like tensile strength, elasticity, yield point, and ductility

- Supports various test types: tension, compression, bending, etc

Advantages and Disadvantages of Universal Testing Machine

Advantages of a Universal Testing Machine (UTM) include accurate results, multi-purpose testing, and wide material compatibility. However, Universal testing machine (UTM) machine disadvantages include high cost, the need for skilled operators, and regular maintenance.

| Characteristic | Advantages | Disadvantages |

| Versatility | Performs multiple test types: tension, compression, bending, shear, etc. | Requires various fixtures and accessories for different tests |

| Load Capacity | Available in wide force ranges—from a few N to 600?kN | High-capacity machines are bulky and expensive |

| Accuracy & Precision | Uses high-resolution load cells and extensometers for exact results | Requires regular calibration to maintain accuracy |

| Test Speed Control | Adjustable crosshead speed for various test conditions | Inaccurate speed control can affect results in sensitive materials |

| Data Acquisition System | Real-time data logging and graph generation via digital systems | Complex software may need training |

| Software Capabilities | Offers automated testing, result analysis, and report generation | Licensing costs and compatibility issues with old systems |

| Compliance Standards | Supports ASTM, ISO, BIS, DIN standards for certified testing | Non-compliance can result in test invalidation |

| Safety Features | Equipped with emergency stop, overload sensors, and travel limit switches |

Improper maintenance may render safety features ineffective |

| Fixture Compatibility | Accepts interchangeable grips for a variety of sample sizes and shapes | Custom fixtures for niche applications may be costly |

| Frame Stiffness | High stiffness ensures minimal deflection, enhancing accuracy | Less relevant in low-load or classroom-grade machines |

| Environmental Compatibility | Can be integrated with temperature/humidity chambers for environmental testing | Requires specialized setups; increases complexity and cost |

| Durability & Reliability | Long operational life with heavy-duty usage in labs and industries | Wear and tear can reduce performance over time |

| Power Requirement | Standard models operate on single or three-phase electricity | High-capacity machines may need special electrical setups |

| Maintenance Needs | Routine servicing ensures long-term accuracy and reliability | Downtime during maintenance can disrupt lab or production schedules |

WHAT IS THE WORKING OF UTM (Universal Testing Machine)?

A universal testing machine is one of the critical tools with a high versatility that can be broadly utilized in the field of material testing. The main and primary purpose of this machine is the assessment of certain mechanical properties of various materials. These materials incorporate polymers, paper, metals, ceramics, and composites.

The best feature of this machine that makes it different from other instruments is that it is explicitly designed to conduct various tests. It is a jack of all trades in the lab testing instruments industry. In total, 37 tests can be performed by customizing the Universal testing machine as per each test.

Some of these tests are:

TENSILE STRENGTH TEST

Test to check how much force is to be applied to the sample to stretch it or elongate it before it breaks.

COMPRESSION TEST

Test to check how much pressure a sample can withstand before it ruptures or damages.

BENDING STRENGTH

To check how much force it takes to bend a sample.

SHEAR STRENGTH

To check how much force it takes to slide apart a material. And many other tests.

The term “universal” highlights that this machine is a solution to any and all needs. This machine can be considered an indispensable asset that can be used in any industry like manufacturing, automotive, construction, material science, packaging, etc.

For instance, if a company has a purpose to develop new alloys for automotive parts, test how durable is the concrete to be used for constructing a house or anything, or ensure the plastic components are safe to use, this universal testing machine can provide the accurate data with utmost precision in order to understand how the materials react when put through pressure that they may face in real life situations.

For various purposes such as pushing, pulling, twisting, or bending, the machine is highly equipped with different attachments and fixtures to place and hold the material and apply the force required as per the test. As the material starts undergoing stress, the UTM starts recording the data regarding the resistance and the deformation of the material until it completely breaks down. This recorded data helps in determining not only the strength of the material but also its elasticity and its performance in real-world situations.

Now hoping on to the main part,

HOW DOES THE UNIVERSAL TESTING MACHINE (UTM Machine)WORK?

Here’s a simple breakdown of what is the science behind the working of this instrument:

STEP 1: SAMPLE PREPARATION

Take a sample of the material to be tested, as per the standard dimensions which is 25 mm by 150 mm for paper or film. For rubber, it should be in a dumbbell shape. After preparing the sample place it between the grippers of the machine.

STEP 2: CALIBRATE THE MACHINE

To apply the force with accuracy, the machine needs to be calibrated according to the requirements of the operator. It is upon operator’s requirements how much pressure needs to be applied and at what speed..

STEP 3: APPLY THE FORCE

According to the set parameters, the machine starts applying the force on the material. The force is applied in the form of push, pull, bend, etc.

STEP 4: MEASURE THE FORCE

After applying the force, the machine measures the amount of force a material can withstand before collapsing or breaking down.

STEP 5: ANALYZE AND RECORD THE DATA

After the test is completed, analyze and record the data at which the material broke down. Measures the data regarding the properties of the product such as its tensile strength, yield strength, etc. You can easily fetch the data in the form of a graph, excel, or even a PDF!

FAQs

What is a Universal Testing Machine Used for?

A Universal Testing Machine (UTM) is used to evaluate the mechanical properties of materials by applying controlled forces such as tension, compression, or bending. It helps determine key parameters like tensile strength, yield strength, elasticity, and ductility.

What does an UTM machine do?

A Universal Testing Machine (UTM) is designed to test the mechanical strength and behavior of materials under various forces such as tension, compression, bending, and shear. It measures how materials react under load, helping determine properties like tensile strength, yield point, elongation, and elasticity.

What is the difference between UTM and CTM?

The main difference between a Universal Testing Machine (UTM) and a Compression Testing Machine (CTM) lies in their functionality. A UTM is a versatile device that can perform multiple tests, including tensile, compression, bending, and shear on various materials. In contrast, a CTM is specifically designed for compression testing only, commonly used for materials like concrete and bricks.

What does UTM measure?

A Universal Testing Machine (UTM) measures mechanical properties like tensile strength, compressive strength, yield strength, elongation, modulus of elasticity, and ductility. These values help determine how a material will perform under different types of stress.

How to select the right UTM for a specific application?

There are several factors that can affect the choice for a UTM such as the range of testing speed, the type of the material, and the load capacity.

What are the components of the UTM?

UTM consists of various components like load cells, HMI screens, grippers, fixtures, load frames, and software.

What benefits does UTM offer?

It is a multipurpose machine that offers various benefits such as quality control, safety, and innovation.

Book your free trial on our testing instruments!

Contact Information:

Phone: +91 9313 140 140

Email: info@testronixinstruments.com

Website: www.testronixinstruments.com