Reviewed by Anurag Mishra (Sr. Technical Consultant)

Industries which deal in transparent products like plastic or glass can often face problems in their products like undetected internal stresses and strains. These are very minute deformations that cannot be detected by checking manually through the naked eye. These stresses are minute deformations within the material that are not visible to the naked eye. These minute imperfections can lead to bigger defects till the end of the product resulting in cracks, weakened product or prone to shatter. This can be harmful in products that require high durability, such as automotive windshields, optical lenses, or medical equipment.

For example, In the glass manufacturing industry, ignoring internal stress can lead to frequent breakage, which is not just a financial loss but also a major safety risk. Let’s say a glass window of your car breaks that can be fatal. You don’t want that for your clients. Similarly, in the plastic industry, if your product is exposed to force or any other unfavorable condition it may break or brittle over time. This will not only cost you financial and operational issues, it will directly affect your brand image in the market and with today’s market being on the top is the only option.

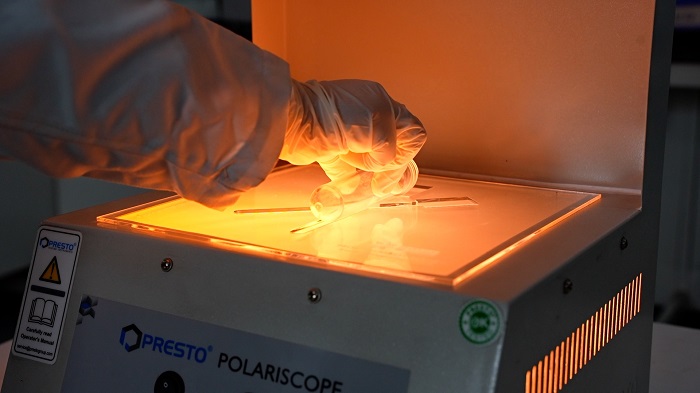

All these problems and one solution, the Polariscope is the ultimate solution to the undetected irregularities, the minute deformations or anything that can turn into a problem shortly. It is a specifically designed tool that can precisely detect even the tiniest bit of irregularity or deformation by using polarized light. When some type of light passes through a transparent material, it experiences several changes depending on the internal structure of the sample. The Polariscope enables you to see those changes without any other specialized instrument.

The Polariscope is an essential tool for material Testing and quality control. It helps you to detect flaws that would go unnoticed otherwise, guaranteeing that only goods with the best possible structural integrity are put on the market. Using a Polariscope in the manufacturing process can help businesses lower the possibility of product failures, raise safety standards, and produce better products overall.

A Polariscope is a technical device designed to detect defects and irregularities in transparent materials. It consists of the following components: a polarizer, analyzer, light source, and specimen stage. The polarizer sieves the light rays letting only light waves travel in a single direction through the specimen. The light source lights up the sample, after which you can easily detect the defects through the window.

Glass Manufacturing Industry

In the glass manufacturing industry, there is a need to check the glass bottles, sheets or other transparent products for any kind of internal stress that can turn into breakage. For example, Windshield that is used in the automotive industry is made sure that it goes under polariscopes to reduce the chances of shattering.

Polymer Industry

The plastic industry conducts polarized testing through the Polariscope to check for strain distribution. Products like plastic bottles, Jars, containers and other packaging materials are tested for uniformity and defects. Conducting testing, addressing and fixing defects at an initial stage will reverse the issues that will occur during the manufacturing process and thus the final product will mould out perfectly and fault-free.

Gems and Jewelry

Polariscopes are essential in the Ge industry as it has the capability to detect and identify internal defects and inclusions in the gems which could be ignored while testing manually. These defects, which can deteriorate the value and durability of the gems, are made detectable through different stress patterns through the polarized light in the polariscope.

Non-Destructive Testing

A Polariscope is capable of conducting Non-destructive tests that is when you conduct testing without harming the product. You can test your product without damaging it while other tests may require steps like cutting, bending, or many other ways. You can test your sample without sacrificing. It allows you to check for internal stress or any other defects without causing issues to the material.

Accuracy and Precision

Polariscopes are committed to precision and accuracy; they are capable of detecting even the tiniest bit of defect in the preform. For industries where precision is kept at the top, polariscope can help.

Cost-Effectiveness

A Polariscope can help you prevent major financial losses. Imagine having a whole lot of faulty final products which you could have saved just by conducting a polariscope test. Detecting and correcting physical deformities or stresses before manufacturing at an initial stage will help prevent a lot of operational as well as functional issues.

Enhanced Product Quality

The Polariscope will help you conduct efficient testing and will allow you to produce products that are free from any internal stress or defect. This will ultimately enhance the end product and increase the rate of customer satisfaction.

1. Preparation of the Sample

2. Setting Up the Polariscope

3. Conducting the Test

4. Analyzing the Results

That is it, you can easily conduct a Polariscope test in 4 simple steps!

Turn the meter of rejections to zero with the Polariscope. Create high-end products with zero faults and errors to stand tall in the highly competitive world of today! From aerospace to glass each industry invests its trust in our Polariscope. Join the team and let’s create an amazing user experience for our customers. Because at last the customer is the king!

Contact us for your first free sample testing and get a deeper understanding of your own product for a better and flourishing future. Let’s fight rejections together! Mail us at info@testronixinstruments.com or simply give us a call at +91 9313 140 140.