Reviewed by Anurag Mishra (Sr. Technical Consultant)

Using cartons, paper bags, synthetic bags, leather bags, etc. for carrying items from one place to another is extremely very prevalent which makes it a norm in society. The materials that are used to make such packaging bags or related products have a tendency to burst or rupture after withstanding bursting strength applied against them to an extent.

In the case of compromised quality of these materials, the scope of contamination of the items packed inside these materials increases which can lead to hefty losses, damage to the product as well as the brand reputation & costly repairs.

The Testronix Instruments has come up with a solution to eradicate the chances of contamination and losses faced by either consumers or manufacturers, called the bursting strength tester. The instrument is designed with absolute precision to assess & determine the bursting strength that a paper, corrugated sheet, leather, synthetic, etc. can withstand.

This helps the manufacturer to segregate the materials according to their relevant durability. The instrument is majorly used in the rigid paper & packaging industry for the assessment of corrugated boxes.

It is vital to understand how exactly the instrument works & functions in order to achieve highly accurate results, determining the precise bursting strength of materials.

The bursting strength tester is a lab testing equipment designed to curb the operator from performing single-handed bursting strength tests with absolute ease and without any hassle for expeditious yet accurate test results.

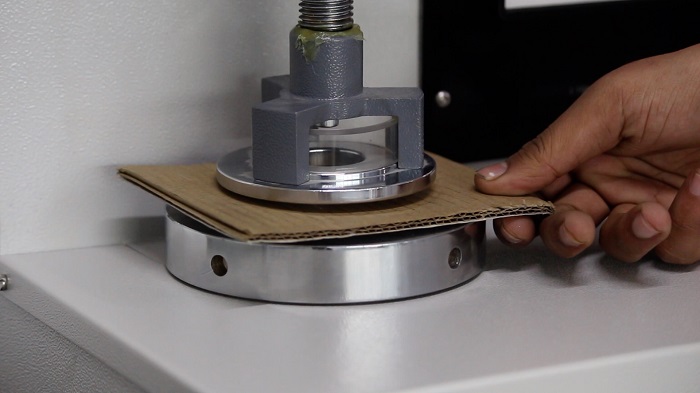

To begin with the bursting strength test, it is highly crucial to make sure that the specimen falls under the category of rigid paper & packaging industry. For example, the specimen can be a corrugated sheet but not a laminate.

The specimen is then placed among the fixtures, specially designed for the placement of the specimen with a rugged surface at the top of it.

After the placement of the specimen, it is necessary to clamp it firmly with the help of the rotating wheel associated with the clampers.

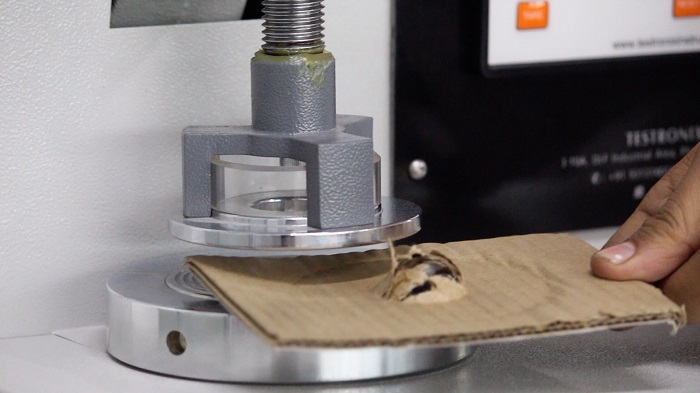

The bursting strength tester machine functions on a hydraulic parameter that exerts pressure on the diaphragm made with neoprene rubber forcing bursting strength on the specimen.

The hydraulic parameter is governed by lab-grade glycerin for better & enhanced testing methodology, reaching maximum accuracy repeatedly.

The specimen bursts after a point, resulting in the depiction of bursting force on the microprocessor-based digital display. However, it is extremely necessary to be aware of the GSM (grams/ square meter) of the material being used.

Now the operator can simply use the formula:

Bursting force = (bursting strength x 1000) / GSM of material

The bursting strength tester machine is also equipped with a lot of features that enhance the operating experience, durability as well as accuracy of the instrument.

The bursting strength tester for carton boxes has certain necessary features that curb the problems of measuring the bursting strength of materials by aiding manufacturers.

The most prominent feature that makes the bursting strength tester digital better than others is the incorporation of neoprene rubber rather than a normal rubber as the neoprene ones are more temperature flexible which enables manufacturers to operate in different parts of the world without worrying about the accuracy.

The instrument also depicts a memory hold feature of up to 9 times. The data can be recorded and attained with absolute facile, aiding the manufacturer to critically analyze the attained results by comparing them with the previous ones.

The grippers of the instrument are designed to have a rugged surface that ensures no slippage of the specimen during the testing course.

These grippers are associated with a rotating wheel for firm clamping that contributes to the sturdiness of the instrument.

The bursting strength tester for carton boxes is loaded with feather touch controls in the control panel which assists the operator in conducting tests single-handedly with minimal human intervention, minimizing the scope of human error.

The bursting strength tester has gained the trust of manufacturers from the rigid paper & packaging industry due to its robust construction. The instrument is made with mild steel material coated with 7-layered powder paint to instill rustproofing properties and avoid corrosion.

All these features incorporated by the bursting strength tester manufacturer make the bursting strength tester, one of the finest and most widely used lab testing instruments in paper and packaging industry.

There are certain questions regarding the instrument that create confusion in the packaging industry which are necessary to be answered.

If you also want to evaluate the bursting strength of corrugated sheet, synthetic, leather & paper materials you can simply place an order to the bursting strength tester manufacturer – the Testronix Instruments. In order to seek further information and knowledge about other lab testing instruments, you can find yourself on our website or you can also contact us via phone call at +91 9313 140 140 or e-mail us at info@testronixinstruments.com.

We aim to provide futuristic technology at your doorstep to help you enhance the quality of your manufacturing and provide the best possible products to the end consumer. Buy the bursting strength tester and improve the quality right now.

Ans. Corrugated papers are used in the production of corrugated boxes which are the prime resources for packaging sensitive & perishable items. To ensure their safety and security during transportation & storage hassles, it is extremely important to assess their bursting strength beforehand and avoid jeopardies or uncertainties at the eleventh hour.

Ans. The bursting strength tester digital is loaded with features like feather touch controls, the grooved structure of grippers for no or zero slippage, the incorporation of neoprene rubber, and other features that encourage ease of testing with consistent accuracy.