A BOD incubator, also known as a Biochemical Oxygen Demand incubator, is a special laboratory equipment to retains stable temperature conditions for biochemical and biological studies. The equipment is mainly utilized for BOD testing to evaluate the oxygen demand of microorganisms in water samples over a given period.

BOD incubators are often used in applications such as plant and animal tissue culture, biomass determination, microbial ecology studies, and much more. This blog post will explore the various uses and significance of BOD incubators in different industries, highlighting why having one is essential for various industrial purposes.

What is a BOD Incubator?

A BOD incubator is a device used to maintain the temperature and humidity of a sample during the biochemical oxygen demand (BOD) test. The BOD test measures the amount of oxygen consumed by microorganisms while decomposing organic matter in water. The incubator must maintain a temperature between 20–25°C and humidity above 90% to ensure that the microorganisms are able to properly decompose the organic matter.

The BOD incubator is an important tool in industries because it allows for the accurate measurement of the amount of oxygen that is consumed by microorganisms. This information can be used to optimize wastewater treatment processes, which is essential for protecting the environment and public health.

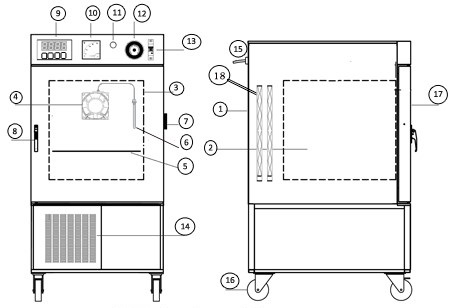

BOD incubator diagram

The BOD incubator provides regulated conditions that benefit biological research, particularly for BOD testing. A BOD incubator consists of an insulated external construction, a stainless-steel chamber, an air-circulating fan, and temperature regulation components. Heating and refrigeration elements control temperature, and the safety features, which comprise both a thermostat and a locking door, guarantee system stability.

Components of BOD Incubators:

Knowledge about the BOD incubator structure and its essential elements enables effective laboratory operation through reliable scientific output. A BOD incubator diagram with label contains these components.

- Exterior Structure: The external part includes insulation layers, which function to preserve optimal interior temperature conditions.

- Inner Chamber: The interior chamber of the device uses stainless steel as its material because it gives durability alongside simple cleaning capabilities.

- Toughened Glass Window: The toughened glass window enables observation of samples without door opening, which avoids temperature variations.

- Air Circulation Fan: Uniform temperature distribution depends on an air circulation fan, which distributes air across the chamber.

- Removable Shelves or Trays: Shelves and trays provide adjustable placement areas that suit different sample sizes along with multiple sample quantities.

- Temperature Sensor: The control system receives temperature feedback from the integrated temperature sensor, which monitors chamber interior temperature conditions.

- Digital PID Temperature Controller: A digital PID Temperature Controller operates with precise functionality to control the heating and cooling systems at desired temperatures.

- Refrigeration System: The refrigeration system depends on compressors to generate cooling that meets requirements below ambient temperatures for specific applications.

- Heating Element: The heating element supplies the heat needed for maintaining chamber temperature and possible temperature increases.

- Safety Thermostat: The safety thermostat functions as a protective system through its capability to stop heating element power when the temperature reaches predetermined threshold levels.

- Control Panel: Through the Control Panel, users can set all operational settings, including temperature exposure duration as well as other parameters.

- Door Handle with Lock and Key: The chamber becomes secure through the combination of the door handle with lock and key, which both control entry while preserving internal environmental conditions.

- Caster wheels: Facilitate easy movement and positioning of the incubator within the laboratory.

BOD Incubator Uses

The Biochemical Oxygen Demand (BOD) incubator is used as standard laboratory and industrial equipment for monitoring biological test environments. This device is essential in multiple applications requiring exact temperature control for microbial cultivation, biochemical assays, and environmental testing. The BOD incubator has many uses, especially for laboratory applications.

1. Wastewater Treatment and Environmental Monitoring

- The measurements of microorganism-induced oxygen consumption in water samples during organic matter breakdown depend on BOD incubators.

- These evaluation procedures let analysts determine wastewater contamination levels while monitoring water treatment procedure effectiveness.

- BOD incubators serve industries and environmental agencies to verify compliance with water pollution control regulations.

2. Microbiological Research

- BOD incubators in microbiology help to study microorganisms by establishing specific temperature parameters for microbial growth.

- Scientists use BOD incubators in microbiology to track bacterial expansion, fungal development, and microbial interconnections in various environmental settings.

- The incubators find extensive applications in pharmaceutical research and food and biotechnology testing laboratories.

3. Food and Beverage Industry

- Food industry scientists use BOD incubators for examining food specimens to assess microbial pollution levels to protect consumer safety.

- BOD incubators aid shelf-life testing through their capability to monitor bacteria and fungi growth under controlled environments.

- Beverage manufacturers apply these incubators during fermentation analysis to measure product consistency.

4. Medical and Pharmaceutical Applications

- BOD incubators represent essential laboratory equipment in pharmaceutical research because they establish reliable conditions for drug and vaccine research.

- BOD incubators serve the pharmaceutical industry through three testing procedures: sterility evaluation, microbial threshold assessment, and product quality monitoring during manufacturing operations.

- The incubators serve medical research labs for their vaccine production and pathogenic agent research requirements.

5. Agricultural and Plant Research

- The BOD incubators enable agricultural research through their applications in plant tissue culture and seed germination experiments.

- The devices offer a balanced temperature controller, which enables scientists to examine plant development patterns while performing genetic experiments.

- The testing and observation of soil and microorganisms within agricultural research depend on available BOD incubators.

6. Biotechnology and Industrial Applications

- BOD incubators enable biotechnology laboratories to conduct enzyme development as well as examine antibiotics and process probiotics.

- Multiple industrial research areas depend on BOD incubators for their studies of fermentation processes and biomass growth together with enzyme activity tests.

- Industrial production of specific microorganisms benefits from incubators, which provide perfect growth and metabolic conditions.

BOD incubator working principle

The working principle of the BOD incubator is to control temperature levels while circulating air through continuous monitoring systems. A thermostat operates through heating elements to preserve the target temperature. The refrigeration system starts its operation upon detecting that the chamber temperature exceeds the set point. The system maintains precise temperature control by allowing heat and cool cycles to work together.

A built-in axial fan distributes air equally in the incubator chamber, maintaining stable conditions while avoiding temperature irregularities. Interior conditions are monitored by a temperature sensor that sends information to the thermostat, enabling it to change its settings for stability maintenance. The exact control of temperature stands vital for tests because any deviation from the set points can modify microbial activity, which affects test outcomes.

The required time of five days commences after the temperature reaches its set level inside the incubator, where microorganisms consume oxygen in the sample. Research personnel use the decreased oxygen level measurements to calculate the BOD value. The results precisely measure the biochemical oxygen demand of the sample because the incubator exclusively obtains oxygen from the water sample.

BOD incubator full form

Full form of the BOD incubator is Biochemical Oxygen Demand Incubator. It’s a piece of laboratory equipment that supports low-temperature controlled conditions (20°C to 25°C) for BOD test analysis, where researchers study oxygen depletion in water sample microorganisms. The BOD incubator includes an insulated chamber, an air circulation fan, a refrigeration system, and a temperature controller element. Wastewater treatment, with environmental monitoring and microbiological research all depend on BOD incubators for their operation.

BOD Incubator Temperature

The standard temperature of 20°C to 25°C operated in BOD incubators serves for microbial activity testing of water quality. A precise temperature control system that includes heating and cooling systems operates inside this device to maintain consistent conditions, which protects experimental results from interference. BOD incubators differ from bacteriological incubators since the former can both heat and lower the temperature below room temperature levels.

Modern BOD measurement models incorporate automatic digital controls and alarm systems that guarantee stable temperature conditions. Maintenance procedures and regular calibration systems guarantee accurate results for both environmental tests and wastewater examinations.

Difference Between Bacteriological Incubator and BOD Incubator

The key difference between the two lies in their temperature regulation and applications. Bacteriological incubators offer only heat control features that serve microbial culture growth; however, BOD incubators combine heating and cooling capabilities, making them perfect for water quality assessment.

Laboratories employ bacteriological incubators and BOD incubators for environmental control, although each device has unique operational principles to fulfill separate scientific functions.

The main function of a bacteriological incubator consists of bacterial culture maintenance while supporting their growth. The system delivers heated conditions that span from 30°C to 37°C because this temperature range supports bacterial growth effectively. The operating principle of these incubators relies solely on heating mechanisms, which allow them to heat above room temperature but cannot lower temperatures below room temperature. Such equipment functions in microbiology laboratories together with medical research facilities and food testing laboratories.

The BOD incubator functions specifically for testing Biological Oxygen Demand (BOD) through measuring water sample microorganism oxygen consumption. A BOD incubator differs from bacteriological incubators by employing dual heating and cooling functions which enable it to operate at 20 degrees Celsius. Environmental and wastewater analysis demands this exact temperature control because it enables the study of microbial activity.

Advantages and Disadvantages of BOD Incubator

A Biological Oxygen Demand (BOD) incubator is an essential laboratory instrument used to create a controlled environment for microbial activity, particularly in water quality testing and environmental analysis. While it offers several advantages, it also has some limitations too.

Advantages of BOD Incubator

The main strength of BOD incubators exists in their exact temperature control capabilities, which are essential for dependable BOD testing results. This specialized incubator provides simultaneous heating as well as cooling capabilities, which enable it to preserve and regulate temperatures around 20°C to 25°C. The correct temperature control mechanism in this device helps to produce accurate Biochemical Oxygen Demand measurements. The incubator ensures testing precision by using a uniform air distribution system that stops temperature changes.

This equipment provides useful capacity in environmental monitoring along with wastewater treatment operations and scientific research facilities. Using this method allows the detection of organic water contamination levels to maintain environmental compliance standards. Digital controls together with automatic settings exist now in modern BOD incubators, which makes operation both user-friendly and efficient.

Disadvantages of BOD Incubator

The BOD incubator provides several benefits to its users yet it comes with specific performance limitations. The continuous temperature regulation mechanism causes high energy usage in BOD incubators, particularly when they possess both heating and cooling features. The operational expenses of using a BOD incubator will increase.

The BOD incubator operates at one particular temperature range, thus preventing its use for bacterial culture growth that necessitates temperatures beyond room temperature. Regular maintenance is necessary for BOD incubators because dust accumulation together with temperature sensor malfunctions, and compressor issues affect their performance.

How does a BOD Incubator work?

A BOD incubator is a temperature-controlled chamber that is used to culture microorganisms. The incubator maintains optimal conditions for the growth of bacteria, yeast, and mold. The temperature, humidity, and CO2 levels are monitored and controlled in the incubator. The culture media is sterilized before use and the microorganisms are inoculated into the media. The media is then placed in the incubator where it remains until the desired cell density is reached.

Why is a BOD Incubator important in industries?

BOD incubators are important in industries because they help to maintain the correct temperature and humidity levels for bacteria to grow. By controlling these conditions, businesses can ensure that their products are safe from spoilage and contamination. By using a BOD incubator, companies can also save money on energy costs associated with maintaining proper storage conditions for their products.

What are the different types of BOD Incubators?

BOD incubators are machines used to grow and maintain bacteria cultures. There are several different types of BOD incubators, each with its own advantages and disadvantages.

The most common type of BOD incubator is the shaking incubator, which uses a motor to shake the culture media and keep the bacteria in suspension. Shaking incubators are very effective at keeping bacteria cultures alive and healthy, but they can be noisy and require regular maintenance.

Another type of BOD incubator is the rotating incubator, which uses a rotating platform to keep the culture media evenly mixed. Rotating incubators are very gentle on bacteria cultures, but they can be expensive and require more space than shaking incubators.

How to choose the right BOD Incubator for your needs

A BOD incubator is a type of scientific equipment used to maintain optimal conditions for the growth and incubation of biological samples. There are many different types of BOD incubators on the market, so it is important to choose the one that best suits your specific needs. Here are a few factors to consider when choosing a BOD incubator:

-Size: The size of the unit will be determined by the amount of space you have available and the number of samples you need to accommodate.

-Temperature range: Make sure the unit can maintain the temperature range required for your specific application.

-Humidity control: Some applications require precise humidity control, so make sure the unit you select has this capability.

-Controls and features: Consider the different controls and features offered by each unit and select the one that offers the most user-friendly interface.

Conclusion

In conclusion, the BOD incubator is an essential tool for industries that require accurate and reliable controls over a wide range of temperatures. This incubator can be used to accurately measure biological oxygen demand as well as other important factors, such as microbial counts.

By using this device, companies can ensure their products meet all quality standards and maintain consistent production with minimal interruption. As technology advances, more uses for this device are bound to arise in order to increase efficiency and productivity throughout the industry.

Contact us today to learn more about the best quality BOD Incubators in India. We will also help you choose the right BOD Incubator that completely fits your requirements.