Reviewed by Anurag Mishra (Sr. Technical Consultant)

When two forces are applied to a material, the forces are referred to as tension, similarly when two forces are applied in an opposite direction of each other on a material they are known as tensile. The material that is exposed to the climate often experiences such tension & tensile forces against them which might break them or elongate them, depending upon the elasticity & ductility of a material.

Luckily, we have the option of using a wide range of materials for the production of various products that hail from absolutely different industries like construction, automotive, aeronautic, textile, pharmaceutical, etc. All these industries have to evaluate the material before utilizing them in the production process and segregate them according to their physical as well as mechanical properties which can only be determined by rigorous testing.

To perform such testing measures and evaluate the quality of materials by assessing the ductility or ductile strength, the leading lab testing manufacturer – Testronix has offered the top-selling and widely demanded universal tensile tester. The lab testing instrument is designed with high levels of engineering and after thorough research & development in order to cater to a wide range of manufacturers by evaluating the tensile strength of various materials like metals, plastics, rubbers, and textiles.

The ability of the instrument to evaluate so many different kinds of materials with the promise of high-quality & precision-based test results allows manufacturers of different industries to store their faith & trust in determining the ductility of materials and then use them in the final products accordingly. The ergonomic & easy-to-use working mechanism of the universal tensile tester is also one of the major reasons behind the top-notch & accurate test result deliverance.

The universal tensile machine is offered with top quality testing procedure that streamlines the process as well as allows the operator to conduct each & every test with absolute seamlessness.

To initiate the tensile test, the primary step that is undertaken by the operator is to condition the specimen perfectly with the help of a dumbbell cutting press provided along with the instrument as an additional accessory. The accessory carves out a dumbbell-shaped structure from the sample, making it a specimen suitable for clampers.

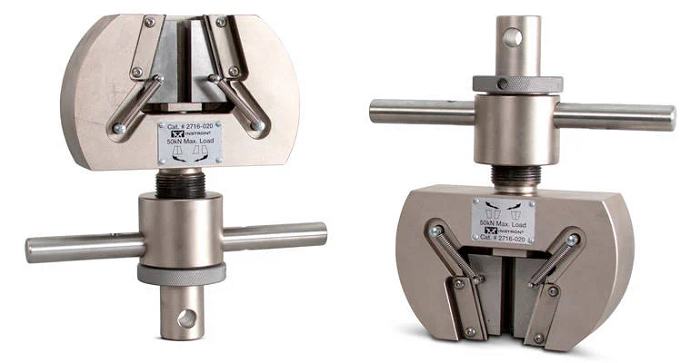

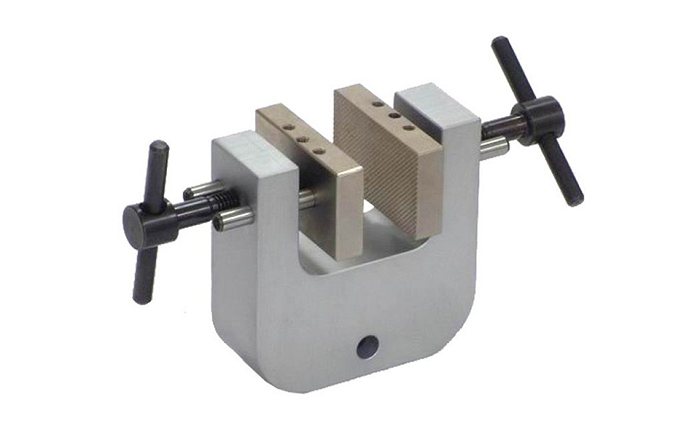

The operator cannot adjust the dumbbell-shaped specimen between the grippers of the instrument and clamp firmly. However, since the instrument has the ability to perform tests on various different materials, it becomes vital for manufacturers to choose from a wide range of specimen grippers along with a wide range of products. The UTM machine is equipped with different kinds of grippers for the perfect clamping of different materials i.e. the same gripper cannot clamp both rubber & metal firmly therefore, the instrument contains:

After choosing the grippers and clamping the specimen the operator can continue with the testing procedure of the instrument. Once the sample is firmly clamped, the distance between the two grippers which is a minimum of 25 mm expands to a maximum of 300 mm under the principle of the constant rate of traverse.

The movement of the grippers is smoothly ensured by the lead screw associated with the instrument, allowing the grippers to move in a linear motion away from each other and forcing tensile strength on the sample.

The sample that is withstanding the tensile strength exerted by the appropriate grippers due to their opposite yet linear movement reaches the peak value before breaking & elongates to its maximum after a point of tensile exertion.

The microprocessor-based digital display of the instrument indicates the peak value that the specimen could withstand before breaking and the maximum elongation levels that the sample has achieved due to the constant rate of traverse method followed by the UTM machine.

The operator can easily record the results indicated on the digital displays associated with the control panel of the universal tensile machine. the operator can also keep track of these records due to the embodiment of the ‘memory hold button’ that can record up to 9 previous test results and help the operator in performing a comparative analysis between the obtained results.

There are certain questions that arise in the minds of the consumer regarding the universal tensile testing machine due to variable applications in variable industries.

The operator must make sure that the instrument has installed the right grippers according to the material that is being tested. Another important factor to make sure of is that the speed of the movement of the grippers is aligned with the designated standards to comply with the guidelines.

The UTM manufacturer – Testronix has made sure that the instrument is loaded with all the necessary characteristics that accommodate a seamless testing procedure. The instrument is offered with feather touch controls for smooth and single-handed operations, various grippers for firm lamping of the specimen, robust build with stainless steel & mild steel to prevent rusting and ensure longevity, ASTM compliance due to the provision of circular lead screw that allows the grippers to move at a speed that is complied with the guidelines of standards, and a microprocessor-based digital display for the indication of the result.

To attain high levels of accuracy in determining the ductility as well as the elongation levels of the instrument, you can get your hands on the precisely designed universal tensile tester straight away by reaching out to our website and placing an order.

For the quotation of the instrument’s price, you can call us at +91 9313140140 or e-mail us with your feedback & requirements for after-sales service at info@testronixinstruments.com.