Reviewed by Anurag Mishra (Sr. Technical Consultant)

Hey! Let's talk about something that has been generating curiosity in the Manufacturing and Material industries- it's called the Salt Spray Test Chamber. Well, did we keep you wondering, "What on earth is this Salt Spray Test Chamber?" your questions will be answered here.

Imagine driving your car along the coast for a few months and finding, to your dismay, rust appearing on all those metal surfaces. Not very cool, huh? That's what happens when materials don't have good corrosion resistance. Fortunately, there's the Salt Spray Test Chamber to ensure that the products you will be using do not end up like a sad, rusty mess. Buckle up because we're getting ready to explore why these chambers are so important to industries all around the world and how they save materials from falling prey to corrosion!

A Salt Spray Test Chamber is kinda like the ultimate stress test for materials. This chamber will simulate the nastiest corrosive environments—like salty ocean air—so you can see how materials and coatings will perform under particularly harsh conditions.

Manufacturers, especially manufacturers of metal-based products, use these chambers to test the anticorrosive properties of their products. The chamber allows them a glimpse into the future when they expose their product-carbon-steel or aluminum-for example salt-laden mist, be it from automotive parts, fasteners, or painted surfaces.

The saltwater solution flows continuously, creating a controlled temperature, and simulating long-term exposure in a corrosive environment. If it can survive the test, it should withstand real life. But what happens if it doesn't? Then the manufacturer knows improvements must be made.

Okay, now here's the juicy part. Think of your shiny new car or fancy outdoor furniture crumbling into dust because of rust within months. Not only would that be disappointing, but it could also mean financial losses and, worse, customer trust down the drain.

This is the reason salt spray testing is a quality control hero. It is applied in any industry whose products make great use of corrosion-resistant materials, like the automotive and aerospace industries, and also the construction industry, especially building facades. Nobody wants his products corroding faster than the sandcastle during high tide!

Here are just a few of the important reasons why this test matters:

Corrosion Resistance: It decides the lifespan of material or coating in corrosion environments and proves to be durable.

Quality Assurance: Products launch with assurance as they have gone through rigorous corrosion tests.

Cost Efficient: The earlier corrosion-prone products are identified, the more a company saves itself from expensive recalls or replacements.

Oh, my, you would be surprised by how many industries depend on this chamber. Okay, let me try painting you a picture.

Automobile Industries: Automobile parts, more especially the metallic ones, are always exposed to moisture. Salt spray testing ensures that you never have to worry about your brake parts or your chassis rusting out after a few rainy seasons.

Electronics: Yes, even electronic components such as circuit boards are tested. It is critical that these parts do not corrode because if they do, you have failures of systems or dangerous short circuits.

Construction: Ever wondered why those shiny metallic pieces on buildings never rust? It's because of salt spray tests that extensively check their coatings and materials.

In simple terms, every industry using materials exposed to moisture—rain, ocean air, or humidity—is making use of salt spray testing to ensure that their products can withstand the weather!

Great question! I can imagine this: a box-like chamber where salty air mists constantly inside. That is basically what a Salt Spray Test Chamber does, only there's a bit to it.

Sample Placement: The material or product sample is placed inside the chamber, and sprayed with a salt solution around it which is normally sodium chloride.

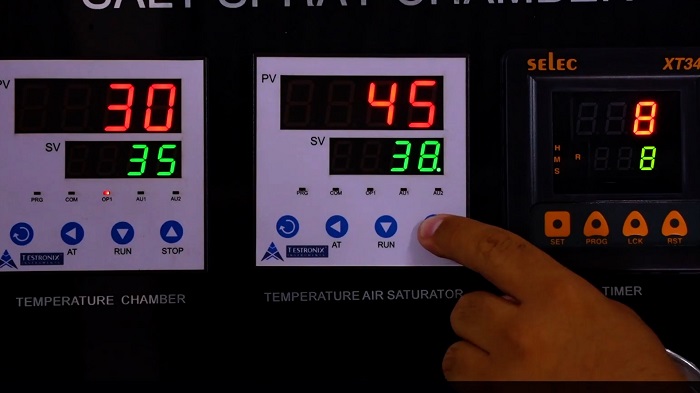

Controlled Conditions: The chamber maintains consistent temperatures, humidity, and concentrations of salt in order for ensure that results will not vary.

Observation Period: Depending on what a test is intended to measure, the material can sit there for hours, days, or even weeks. All that time, the sample remains constantly exposed to salty mist replication of the years in real exposure in a much shorter period.

Results: After the test, the manufacturers check for corrosion signs like rusting, blistering, or peeling. These results are reported back to the manufacturer of the material about how well the material is expected to perform in the actual environment.

Now that you know why these chambers are of so much importance, let's talk about The champions of test instruments! We have salt spray test chambers that are state-of-the-art, giving precise, reliable results. Our chambers are to ensure that you stay ahead of the corrosion curve and ensure your product meets not just but exceeds your quality expectations. Top 3 FAQs

Variables such as temperature, humidity, and the concentration of a salt solution have considerable influences on test results. General conditions should be kept constant throughout the entire test.

Additionally, some common issues include temperature variation and uneven spray patterns. By adjusting the thermostat, checking the safety switch, and scheduling maintenance, many of these issues can be solved

Usually, metals, coatings, plastics, and painted surfaces are tested for corrosion in the salt spray chamber.

So, if you produce products that should last for generations—and probably centuries of corrosion—do not miss the Salt Spray Test Chamber. Trust me, your customers will thank you for it!