Do you feel that your packaging cost is too high? And despite spending so much the quality of the corrugated boxes are still low?

If you wish to reduce your cost of packaging and increase your quality, continue reading!

At Testronix, we understand just how critical packaging is in protecting products during transit and storage. The box compression tester stands out as an essential tool for ensuring packaging integrity. The compression test is essential to ensure that the corrugated boxes adhere to various industrial standards of quality.

Enhance your profits with sturdy and reliable packaging.

When products are at risk of damagne, it can lead to significant financial losses, customer dissatisfaction, and a tarnished brand reputation.

However, all these problems can be solved by using the box compression tester. This instrument measures he compressive strength of packaging materials, providing valuable data that ensures that manufacturers and quality control professionals make informed decisions.

Our box compression tester is not only delivering accurate test results but is also cost effective.

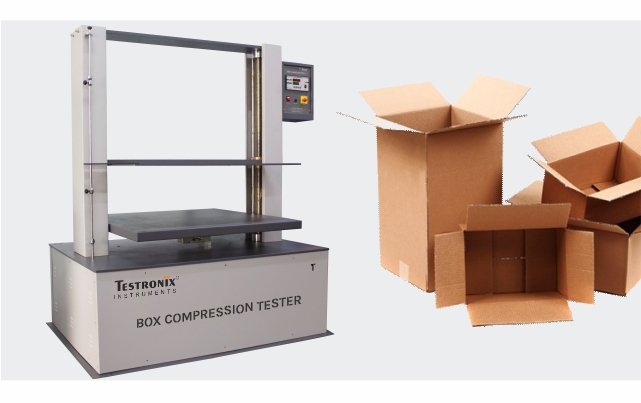

What is a Box Compression Tester?

A box compression tester (BCT) is a specialized instrument used to determine the compressive strength. It simulates the conditions that a box might encounter during stacking, and transportation. By applying a compressive force until the box deforms or fails, the tester provides critical data on the box's load-bearing capacity.

The panorama touch screen model allows manufacturers and our customers to save time, store numeric data, view the results graphically an d receive accurate results.

How Does a Box Compression Tester Work?

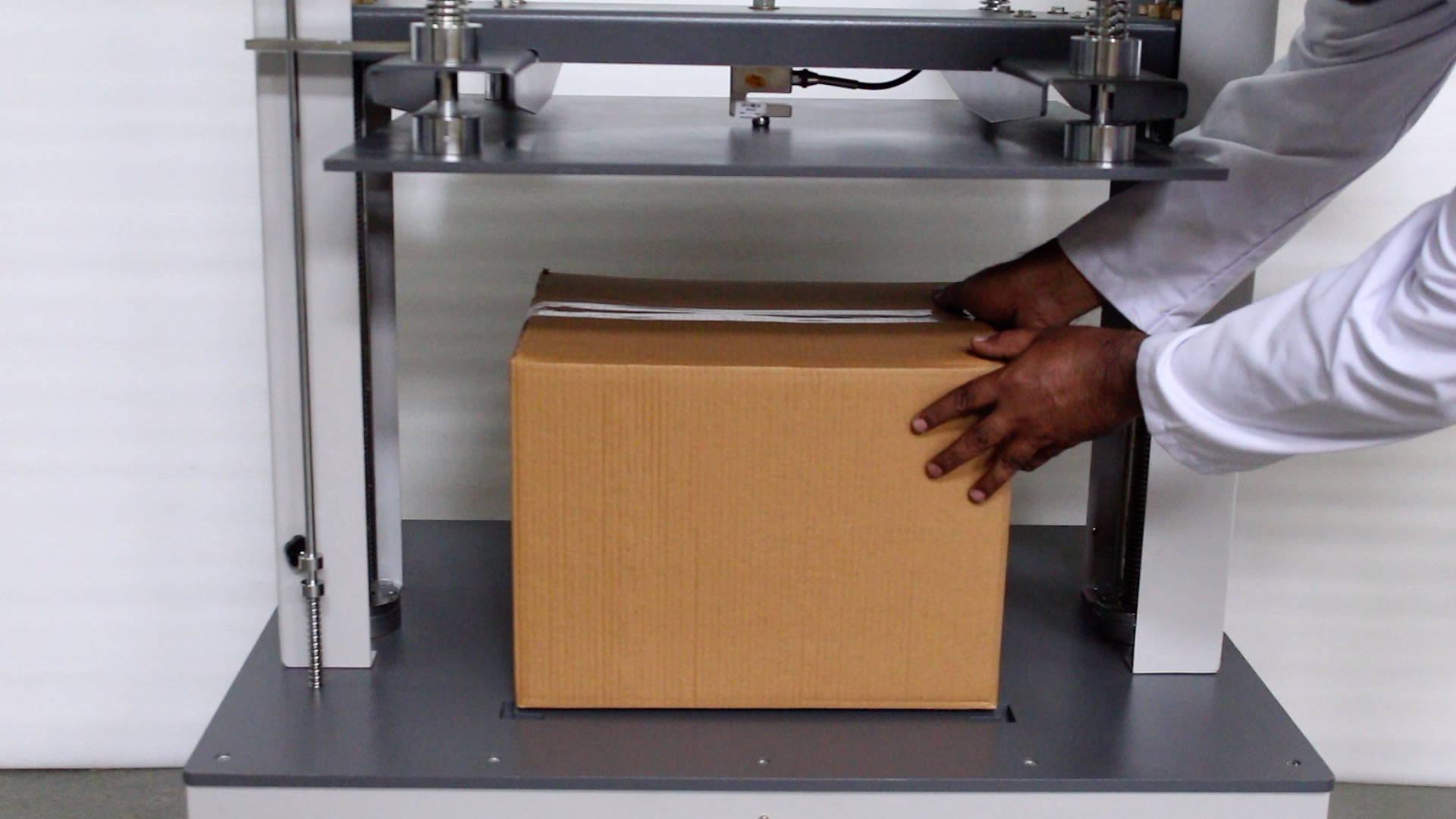

The operation of a box compression tester is based on a straightforward principle: applying controlled compressive force to a box and measuring the response. The following are the steps:

- Sample Preparation: The box to be tested is placed on the platform of the tester. It is essential to ensure that the box is empty and properly aligned. One must ensure that the size of the corrugated box is smaller than the compression plates.

- Setup and Calibration: The tester is calibrated to ensure accurate readings. At testronix, this calibration is done periodically to ensure accurate results. Parameters such as the rate of compression and the maximum force to be applied are set according to industry standards or specific requirements.

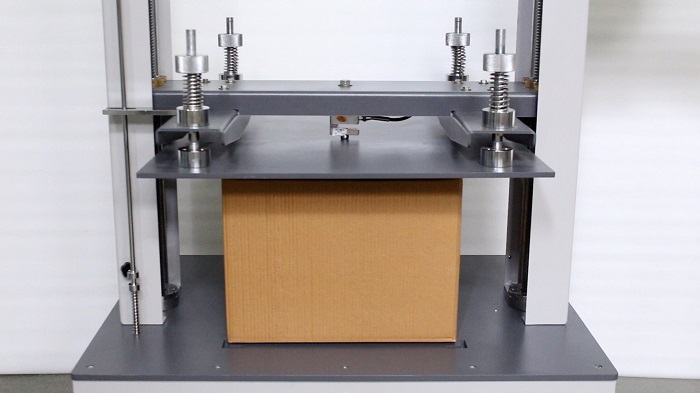

- Compression Test: The machine applies a compressive force to the box. The force is gradually increased until the box reaches its failure point. The tester records the force at which the box deforms or collapses.

- Data Analysis: The recorded data is analyzed to determine the box’s compressive strength. This information is crucial for assessing the suitability of the packaging for various applications. In the computerised model, this data can be stored effortlessly, while the panorama touch screen model provides the opportunity of representing data graphically.

Applications of Box Compression Testers

Box compression testers are used across various industries to ensure packaging quality. Some of the key applications include:

- Paper and packaging industry: With companies relying heavily on robust packaging to ensure products reach customers in an intact state; Box compression testing helps in selecting the right materials and designs for shipping boxes. Our instrument ensures that you are fearless one day before an audit. It guarantees zero rejection.

- Food and Beverage Industry: Packaging in this sector must meet standards of quality to protect perishable items. This testing ensures that boxes can withstand stacking and transportation. Thus, prevents any compromise on quality.

- Pharmaceuticals: Ensuring packaging integrity in the pharmaceutical industry is critical. Box compression testers help in evaluating packaging quality that protects these sensitive items from damage. You can not only reduce your packaging cost but have superior packaging.

Why is the box compression tester necessary?

- Quality Assurance: By ensuring that packaging meets the required standards, businesses can reduce the risk of product damage and returns, leading to increased customer satisfaction. You can now stay that packaging would no longer be a hassle.

- Cost Savings: Identifying the optimal packaging materials and designs helps reduce material costs and minimize waste.

- Compliance: Many industries have regulatory requirements for packaging. Box compression testing ensures compliance with these standards, avoiding potential legal issues.

- Brand Reputation: Delivering products in pristine condition enhances brand reputation and builds customer trust. Your packaging reflects your reputation.

Research in the field of packaging science has provided valuable insights into the effectiveness of box compression testing. Studies have shown that factors such as the box materials have different levels of compressive strength.

For instance, Research indicates that the fluting and linerboard combinations in corrugated boxes play a crucial role in determining their compressive strength. You can use this wonderful piece of information to choose your corrugated boxes wisely.

In fact, Advanced materials, such as those with enhanced moisture resistance or reinforced fibers, have been developed to improve performance. However, how can you decide which material is appropriate for your requirement? You can evaluate this by conducting the compression test.

In addition to the raw materials, the design of a box also affects its compressive strength. Factors such as box dimensions, the arrangement of flaps, and the presence of reinforcements contribute to the overall strength.

It has been recently highlighted, that the importance of optimizing box design to achieve the best performance while minimizing material usage. Finite element analysis or the FEA, is often employed to simulate and optimize box designs. Environmental conditions can also impact the performance of packaging. Studies have shown that higher levels of humidity can weaken corrugated boxes, reducing its compressive strength. To prevent this and maintain standards of quality, book the box compression tester ASAP!