Tensile strength is of utmost importance across various industries. It is crucial because of the impact it has on safety, performance, and the materials that are used in the making of different products.

To maintain the integrity of products, optimize designs, and make durable products it becomes important to know the tensile strength of the material firsthand. You must be wondering what exactly is tensile strength. How is it important? Why is it important? How is it calculated etc etc? So let's dive deep into it!

What is tensile strength?

Tensile strength is typically a key indicator of the strength, durability, and reliability of the material. The maximum amount of force, in the form of either pulling or stretching, that a material can withstand before it is damaged or breaks down, is known as the tensile strength of that material. Megapascals (MPa) or pounds per square inch (PSI) are two common measurements of force per cross-sectional area used to quantify tensile strength.

Tensile Strength Definition and Meaning

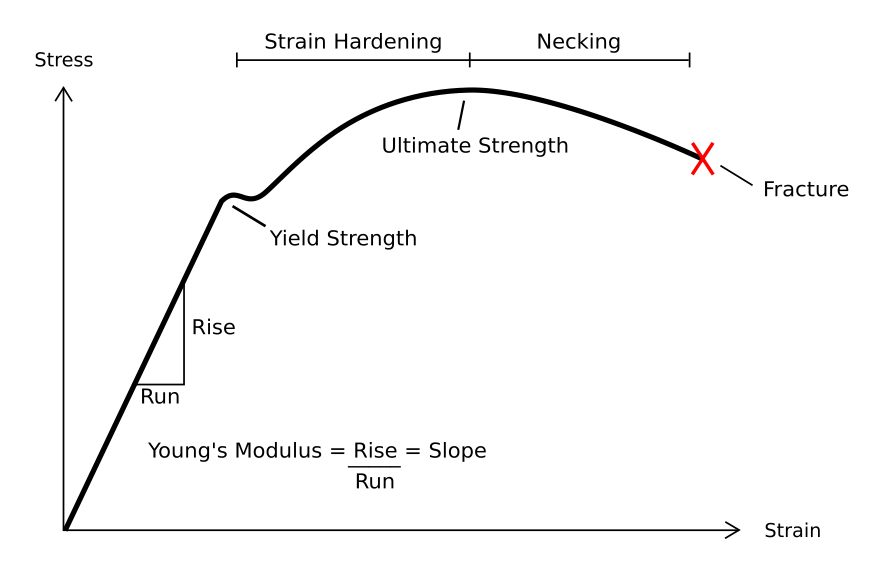

The tensile strength is defined as the maximum amount of stress that a material can withstand before breaking or fracturing. It is calculated by dividing the maximum tensile force by the original cross-sectional area of a specimen. It works on the principle that when stress is increased in a material, the bond between their atoms is stretched and eventually broken.

When stress is applied to a material, it is in the elastic region, and the removal of stress gets it back to the original shape of the material. However, when the amount of stress is continuous, it enters into the plastic region, the chemical compound of the material gets altered, and reversing to the original shape is impossible.

The tensile strength for different materials is different. Industries like manufacturing use tensile testing machines to evaluate the tensile strength of materials to ensure the durability and reliability of materials for various application purposes.

Tensile Strength Formula and Unit

The formula of tensile strength is used to measure the maximum bearing load of a material. The tensile strength is calculated as the force exerted on the material or specimen divided by the cross-sectional area of a material.

Tensile Strength Formula: S = P/A

Where S is the tensile strength, P is the force required to break, and A is the original cross-sectional area. Here the original cross-sectional area refers to the initial area of the sample before any deformation occurs.

This formula determines the highest stress that a material can withstand while being stretched or pulled before breaking.

For example, the tensile strength of steel is typically between 36,000–50,000 psi but can be as high as 58,000–70,000 psi.

Tensile Strength Units: The international standard for tensile strength is Pascal or Mega Pascal (MPa) which is equivalent to N/mm2. Other common units for tensile strength –

Megapascals (MPa): Widely used in engineering and materials science.

Newtons per square millimeter (N/mm²): Equivalent to MPa (1 N/mm² = 1 MPa).

Pounds per square inch (psi): Common in the United States.

Kilopounds per square inch (ksi): Used for materials with high tensile strengths (1 ksi = 1,000 psi).

How the tensile strength of the material is measured?

The tensile strength of a material is measured using the Tensile Strength Tester. This machine applies a controlled tensile force on the sample that is needed to be used, to observe when it breaks down. This force is then recorded and divided by the cross-sectional area of the material to measure the tensile strength.

A tensile test is easy to conduct and can be performed in a few steps. The steps involved are:

STEP 1: SAMPLE PREPARATION

There are specifications according to which the sample needs to be prepared. The sample must be in the form of a dumbbell.

STEP 2: APPLY THE FORCE

After preparing the sample, place it properly between the grippers. The sample will be pulled apart to check its tensile strength.

STEP 3: RECORD THE DATA

Engineers can determine a material's tensile strength by using a tensile strength tester, which records the force applied and the material's response to it.

Why is the tensile strength important?

SELECTION OF THE MATERIAL

Tensile strength plays an important role in the selection process of the material. Material needs to be carefully chosen by identifying the maximum force it can withstand during the transit.

SAFETY

There are various industries that produce materials that are subjected to extreme pressure or force when put through real-life situations such as aerospace, construction, etc. It becomes important for such industries to ensure that the tensile strength of their materials is adequate for safety purposes. Because if their material fails under pressure it can lead to some consequences.

LONGEVITY OF THE PRODUCT

The key selling point of some industries is the durability of their products. In industries like automotive and electronics, the products are mostly made with material whose tensile strength is higher to achieve long-lasting and durable products.

COST EFFICIENT

When the company gets to know how strong the materials are by their tensile strength, it gives manufacturers the choice regarding what material to use and how. This reduces the wastage of the company’s resources by already knowing which material is too strong or which material is too weak and cannot serve its purpose properly.

You must be curious about how exactly engineers can measure the point at which the material can start breaking and how these points affect the quality and durability of the material. Don't worry your curiosity will be satisfied here!

Tensile Strength of Some Notable Materials

Tensile strength is a key mechanical property that indicates the maximum amount of tensile (pulling) stress a material can withstand before failure. It is crucial in determining the suitability of materials for various applications. Below, we focus on two specific materials: the 8.32 screw and Steel 1084.

1. Tensile Strength of 8.32 Screw (Grade 8.8): For an M8 screw with a grade 8.8, the tensile strength is approximately 800 MPa. This is a high-strength screw grade, suitable for applications where significant mechanical stress is expected. The number "8.8" represents the material’s tensile strength in MPa, with "8" indicating 800 MPa, and the second "8" denotes the yield strength, which is about 80% of the tensile strength.

2. Ultimate Tensile Strength of Steel 1084: The ultimate tensile strength (UTS) of Steel 1084 is typically around 750 MPa. This makes it a relatively strong material, ideal for applications that require durability and hardness, such as in the production of cutting tools and blades.

These two materials, the 8.32 screw and Steel 1084 offer different levels of tensile strength, making them suitable for various engineering and manufacturing applications.

Yield Strength Vs Tensile Strength: What is the Difference

The difference between yield strength and tensile strength is that yield strength refers to the maximum stress a material can handle without permanently changing its shape, while tensile strength is the maximum stress it can withstand before breaking.

In simple terms, yield strength is the point where a material starts to deform permanently, and tensile strength is the point where it breaks. Understanding these properties helps engineers choose the right materials for structures and products, ensuring they can handle expected loads without failing.

TIME TO CLEAR SOME DOUBTS!

What are the factors that can affect the tensile strength of a sample?

There are various factors that can have an impact on the tensile strength of the material, such as the temperature, shape and size of the sample, the load capacity, and at last the composition of the material/sample.

How is the tensile strength different from the material’s other strengths?

The tensile strength of a material is defined as the resistance of a material to be pulled apart whereas the other strength of the material is the compressive to resist being crushed or broken down.

Can tensile strength be varied within the same sample?

Yes, it is absolutely possible that the tensile strength can be varied within the same sample. It can be because of the effect of various factors such as processes of manufacturing, the presence of some defects, or the treatment of heat.