Reviewed by Anurag Mishra (Sr. Technical Consultant)

Are you tired of your products falling short when it comes to durability and resistance against corrosion? If yes, then it is important for you to conduct quality tests with standardized laboratory testing equipment. This can be done with the help of salt spray chamber FRP digital.

This highly advanced laboratory testing instrument ensures reliable corrosion testing results and ensures that your products remain free of corrosion. Equipped with a user-friendly interface, the FRP digital salt spray chamber allows professionals to effortlessly navigate through various testing parameters such as temperature, humidity, and acidity levels. You can quickly perform quality assurance on materials with a salt spray chamber.

In this blog, we will discuss about the proper placement and preparation of testing samples for salt spray tests. But before that, we will focus on the salt spray testing and its purpose.

Salt spray chamber testing, also known as salt fog testing or salt corrosion testing, is a widely used method for evaluating the corrosion resistance of materials and coatings. This type of testing involves exposing test specimens to a highly corrosive salt spray environment in order to assess their ability to withstand corrosion.

The concept behind salt spray chamber testing is based on the principle that the presence of chloride ions in a corrosive environment can accelerate the corrosion process. In this type of testing, the test specimens are exposed to a controlled mist or fog of sodium chloride (NaCl) solution, which simulates natural environmental conditions such as coastal areas where salty sea air can cause accelerated corrosion.

Salt spray chamber testing plays a crucial role in various industries such as automotive, aerospace, marine, and construction. It helps manufacturers determine the durability and quality of materials and coatings by testing them against corrosion. This type of testing is particularly important for products that are exposed to harsh environmental conditions like high humidity levels, extreme temperatures, and exposure to corrosive substances.

In addition, salt spray chamber testing is an essential part of quality control processes for companies producing metal components or structures that will be used in different industries. By subjecting these materials to simulated environmental conditions through salt spray chamber testing, manufacturers can identify potential weaknesses or flaws early on in the production process and make necessary improvements.

We at Testronix have designed a high-quality salt spray chamber testing instrument that makes it easy for manufacturers to conduct salt spray tests on the materials.

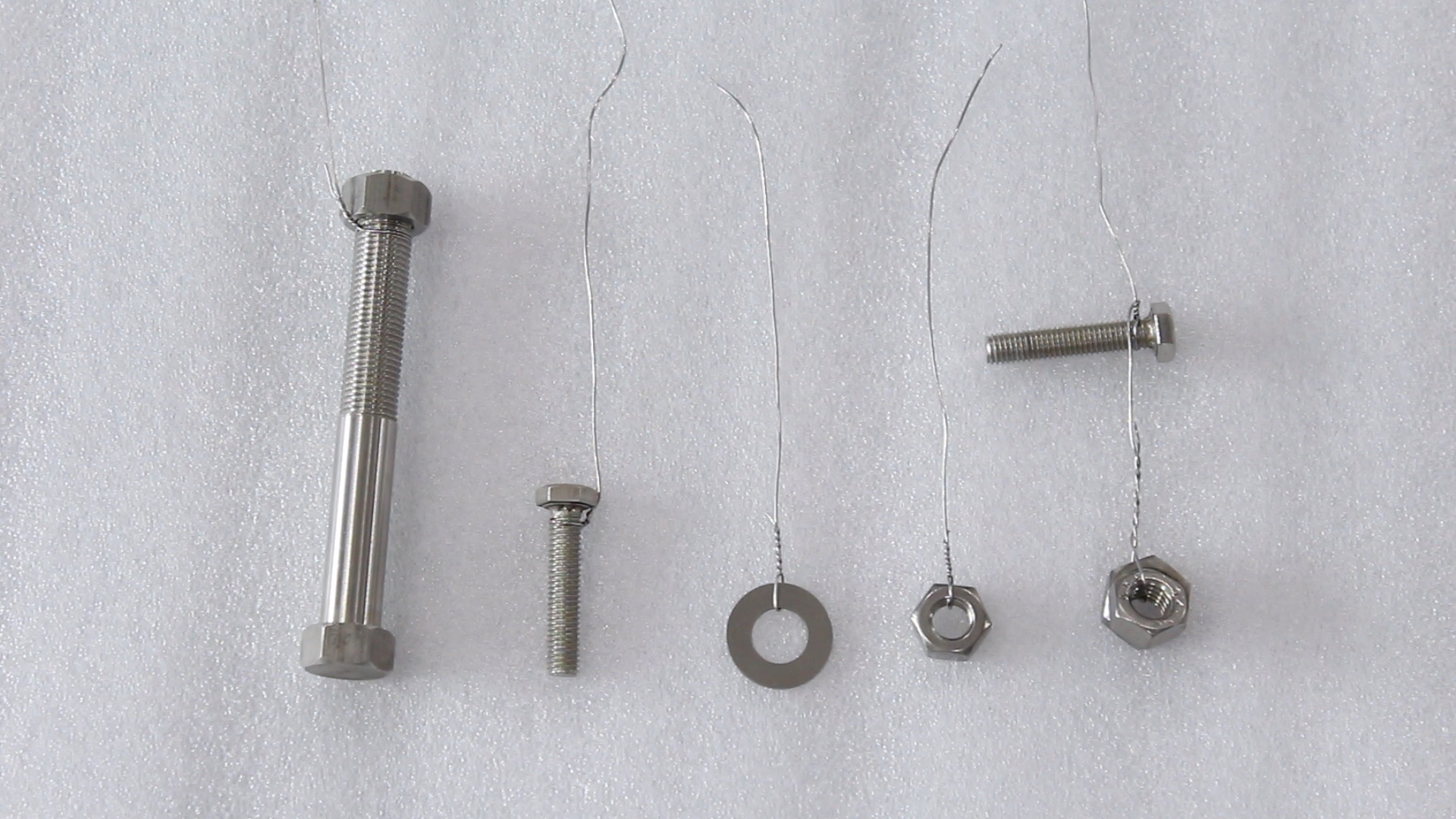

Now, let us discuss some easy-to-follow steps for preparing and placement of test specimens.

When preparing test specimens for salt spray chamber testing, it is important to ensure that they meet the necessary test standard requirements. Different industries and applications may have specific standards that need to be followed in order to accurately simulate real-world conditions and obtain reliable results.

Below we have listed the steps for preparing and placing the test specimen for salt spray test.

Note- In case of hanging the samples, make sure the hanging strips are of material resistant to corrosion.

Note- In case of hanging the samples, make sure the hanging strips are of material resistant to corrosion.

Once the specimen is placed accurately then you can commence the test. If you want to know more about the salt spray chamber price, or any other information then give us a call at you can easily give us a call +91 9313 140 140 or email us at info@testronixinstruments.com. We will provide you with information for all your needs and queries.