Reviewed by Anurag Mishra (Sr. Technical Consultant)

In industries like flexible films and especially packaging, the strength and durability of the material is vital. Damages in the later stage of the production process can hinder the product performance as well as the structural integrity. Testronix provides the ultimate solution in the form of a Dart Impact Tester. It’s engineered specially to meet all your requirements and deliver accurate and efficient test results to enhance your product.

The precision of results is due to the working mechanism of the model which involves the following:

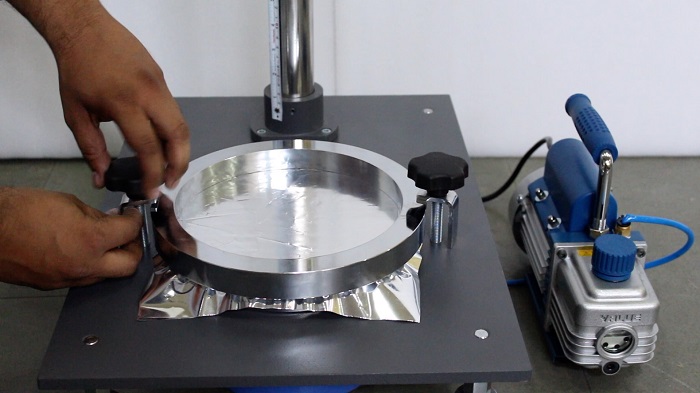

The procedure starts with creating a sample of the plastic film or flexible laminate. The sample is put on a testing platform and fastened using circular annular clamping mechanisms. These clamps keep the sample securely in place, preventing movement or slippage during the test. Proper sample securing is critical because it keeps the material immobile, ensuring the accuracy of the impact measurement.

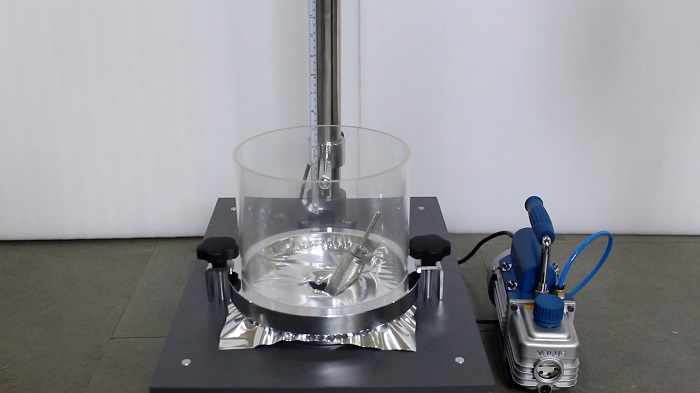

The process involves positioning a dart over a sample using an electromagnetic system for precise control. The drop height can be adjusted to replicate different impact scenarios. The dart then falls under gravity, with impact force determined by the fall height and dart weight.

When the dart contacts the plastic film or laminate, the tester measures the force needed to break the material. This measurement is recorded and shown on the tester's digital LED screen. The digital display gives customers a clear and precise assessment of the impact resistance, allowing them to quickly comprehend the data.

The Dart impact test results are analyzed to determine if the plastic film or laminate passes the impact resistance criteria. The data assists manufacturers in determining the durability of their materials and ensuring that they are appropriate for their intended uses. This study is critical for ensuring quality control and making educated material and product design decisions.

There are a range of features that make the Dart Impact Tester a trusting instrument:

One of the Dart Impact Tester's most notable characteristics is its changeable drop height, which can be set between 660 mm and 1524 mm. This adaptability is essential for performing testing under changing conditions since varied drop heights can replicate different impact scenarios. The tester allows users to alter the height, allowing for a more in-depth investigation of the plastic film's impact resistance. This function guarantees that the material is subjected to a variety of impact pressures, offering a full assessment of its durability.

The Dart Impact Tester has a digital LED screen, which is essential during the testing procedure. This panel delivers clear and exact impact force readings, allowing users to easily acquire correct findings. The digital display avoids the uncertainty sometimes associated with analog meters, providing fast feedback on test results. By legibly presenting data, the LED screen makes it easier to analyze outcomes and helps users make educated decisions faster. This function improves testing efficiency and assures that measurements are consistent and trustworthy.

The Dart Impact Tester employs circular annular clamping mechanisms to keep the plastic film or laminate in place during testing. These clamps are intended to prevent material sliding, which may impair the precision of the test findings. The strong clamping mechanism holds the sample securely, allowing for accurate impact readings and consistent testing circumstances.

The tester has an innovative electromagnetic hold and release mechanism, which is critical to the device's proper operation. This mechanism holds the dart securely until precisely released, providing for smooth and controlled functioning. Electromagnetic technology improves the precision and reliability of impact readings by reducing mechanical friction and ensuring precise release time.

The Dart Impact Tester offers several benefits:

The powder-coated mild steel and strong metallic base make the tester both durable and sturdy. This longevity is critical for ensuring constant performance throughout time.

The flexibility to alter the drop height and dart head diameter provides for more flexible testing. Manufacturers may simulate various situations to see how different films function under varying impact pressures.

The tester offers exact information on the impact resistance of the plastic film by measuring the force with which a falling dart ruptures it. This information is critical to ensure that the film can withstand external forces during handling and transit.

The Dart Impact Tester is simple to use thanks to its digital LED screen and ergonomic design. This simplicity reduces the chance of mistakes and assures consistent outcomes.

The tester's precision and thoroughness in impact testing helps manufacturers prevent costly field failures. Investing in a Dart Impact Tester can ultimately save money by reducing the chance of product failures.

The Dart Impact Tester runs on a single-phase 220V AC power source, which is common in many electrical systems. This compatibility guarantees that the tester may be readily incorporated into current settings and does not require specialized power sources.

The Dart Impact Tester complies with various industrial standards, including IS 2508:1984(R2003) and ASTM D1709-16A. Compliance with these standards guarantees that test findings are credible and accepted across the globe.

The dart-holding mechanism can support weights up to 2 kg. This capability enables the tester to handle a diverse range of testing circumstances, making it appropriate for a variety of materials and film kinds. The Dart Impact Tester's capacity to handle multiple dart weights increases its adaptability, allowing it to suit a wide range of testing demands.

DON’T MISS GETTING YOUR DART IMPACT TESTER!

To know the Dart Impact Price, get a quotation now. You may reach out to us at +91-9313140140 or email us at info@testronixintruments.com