Reviewed by Anurag Mishra (Sr. Technical Consultant)

Industrialists face the challenge of ensuring that the material supplied to them is of quality in this quality-consciousness age. The mechanical properties, like tensile strength, are not easily measurable without the use of proper tools. There is heavy dependence on archaic and imprecise methods, which brings about product failures and increased costs.

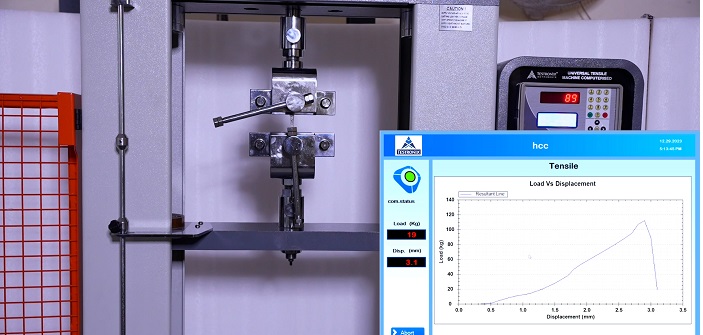

Universal Tensile Testing Machine: This is a highly valuable tool that simplifies the process of material properties evaluation under tension, compression, and bending.

This blog explores how this advanced tool has transformed quality control in various industries, highlighting its uses, benefits, and why Testronix is a trusted name in tensile testing.

For more than 11 years, Testronix has been a leading provider of testing instruments for such huge clients. Reliable instruments manufactured by Testronix assist customers in improving quality control with advanced technology and strong support.

The company has a great name for waste reduction, reducing costs, and maintaining the reliability of products. Success with Testronix brings innovative technologies, extensive research, and years of experience. UTM instruments manufactured by them are regarded as highly robust, accurate, and user-friendly.

A UTM, is a necessity in every quality control lab and helps in assessing the mechanical properties of materials through tensile, compression, bending, and shearing forces to ensure that products meet safety, durability, and quality requirements.

The UTM is very important because of its versatility. It can be used to test materials from metals, plastics, composites, and so much more. Therefore, material manufacturers can ensure that the materials behave well to stress on real-life applications and perform without performance or deterioration in safety and durability.

One of the essential parts of mechanical testing is tensile testing. In tensile testing, the material undergoes tensile strength, yield strength, elongation, and ductility by pulling. This provides knowledge to the manufacturing team about the elasticity and toughness of the material and its resistance towards tension.

A 2023 study by the Global Testing Materials Association found that businesses using modern UTM equipment experienced a 20-25% reduction in product failures from better material testing, improving safety and saving time and resources on recalls.

A UTM saves companies time and money. Traditional testing typically proves costly and time-consuming with numerous steps and instruments. A UTM offers an all-in-one solution to get accurate information on material properties.

Companies employing Testronix UTMs report saving 15 to 20% in production costs, amounting to millions of dollars every year. It saves on multiple setups with the help of automation so that the samples can be tested faster without compromising accuracy.

Let's see how this leads to actual savings:

Labor Costs: Machines do not require labor. At most, they require high-value technicians to work on them.

Reduced Waste: Proper testing minimizes material failures, leading to less waste and improved raw material use.

Fewer Recalls: Quality at the source prevents costly recalls.

A proper UTM setup would enable a business to save ?500,000 to ?1,000,000 in costs related to testing annually.

The UTM is utilized in different companies and uses:

Metals: Testing tensile strength and ductility for structural integrity in automotive and aerospace parts.

Elongation, tensile strength, modulus of plastics Measurement in packaging, electronics, and consumer goods.

Textiles: Testing fabric durability and flexibility is essential for apparel and industrial sectors.

Composites: Testing lightweight, high-strength materials for construction, aerospace, and renewable energy.

Rubber: Ensuring products meet flexibility and toughness standards for automotive and footwear industries.

These applications show the universal appeal of the UTM and make it indispensable in any modern lab.

The UTM tests many other materials, for example, metals, plastics, rubbers, textiles, and composites. The UTMs are highly significant for industries concerned with the strength and performance of materials.

UTMs allow for accurate testing data, thus organizations avoid failed product, waste, and quality control improvements. This can save ?500,000 to ?1,000,000 a year by saving on costs towards testing and recalls.

A UTM is essentially a load frame, load cell, grips or fixtures, and a control system. The load frame supports the specimen, while measurement of applied forces is provided by the load cell. The grips are those that hold the sample in place, and the control system deals with data processing and operation control.

Poor maintenance, calibration errors or misplaced grips, and machine malfunction are some of the problems often encountered with UTMs. Regular maintenance, calibration, and alignment checks are very essential for obtaining accurate results from a UTM.

A UTM works by applying a tensile force upon a specimen till it breaks. The elongation and force applied is measured by the machine, giving data relating to tensile strength, percentage of elongation, and modulus of elasticity. These parameters are used to understand the mechanical behavior of the material.

UTMs The Universal Tensile Testing Machine elevates product safety, quality, and durability in industries. Testronix ensures accurate and efficient testing that will save you and your money. So, if you're ready for quality control on another level, just get a Testronix UTM right today. Let us help you find the perfect solution for your business needs.