Reviewed by Anurag Mishra (Sr. Technical Consultant)

During the production process, packaging goes through several stresses such as storage, transport, handling etc. To identify any weaknesses or shortcomings in packaging, evaluating compression strength of boxes becomes crucial. To tackle this problem, Testronix has engineered an advanced solution in the form of “Box-compression tester: BCT panorama”. This testing instrument offers precise and reliable tests due to it’s microprocessor-based high-speed controller and advanced technology.

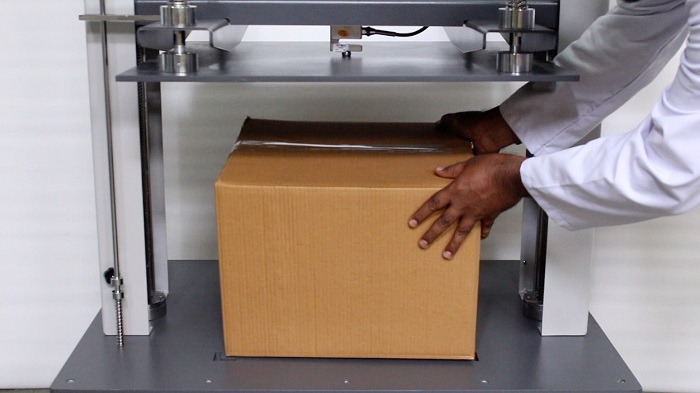

For the testing process, the packaging is placed on the testing platform post where a compressive force is applied. Precise sensors and technology is used with the help of the microprocessor-based high-speed controller. This control panel monitors the box’s response to the force applied providing insight into its functionality. Hence, this feature of the Testronix Box compression tester provides accurate and timely results.

The users can set test parameters, monitor the testing process, and view results. The user experience is enhanced with this 7-inch TFT LCD color screen, providing detailed and clear results of the tests. Thus, the LCD display makes it accessible to all with limited technical training along with efficient results.

Box compression is a necessary tool for several industries. To cater to all these different tools, the BCT panorama is engineered to handle various box sizes and materials, making it a versatile tool for quality control laboratory testing

Testronix makes its box compression tester accessible to users of all level of skill with its programming language. Along with 16 different language inputs, this is designed for global use for ease of operation. Safety of HMI is ensured along with QR code generated management. Users may also use the instrument through mobile devices, offering flexibility and convenience.

Accurate and Reliable Results: The microprocessor-based high-speed controller and precision sensors provide consistent and predictable readings. This degree of precision is critical for determining the strength and durability of packing materials.

Cost savings: Timely understanding of the packaging’s shortcomings makes it easier for the manufacturers to make sound decision while selecting materials and avoid incurring huge losses for repair and replacement.

User Friendly: The user experience is enhanced with The tester's big touchscreen display making it simple to use. Thus, it’s accessible for individuals with limited technical knowledge as well

Global Usability: The BCT Panorama is a flexible tool for global organizations since it supports several languages and can be utilized in a variety of places throughout the world

Operational Efficiency: The ability to remotely fix issues and manage the tester via mobile devices reduces downtime and improves operational efficiency. This guarantees that the testing process runs smoothly and consistently.

Safety and Durability: Surge protection systems and thorough endurance testing guarantee that the tester is both safe to use and constructed to last, offering long-term value to organizations.

Real-time data transfer and status reporting: enable users to carefully monitor the testing process and make necessary modifications. This guarantees that any faults are handled quickly and testing results are correctly recorded.

Versatile Applications: The BCT Panorama is intended to handle a variety of box sizes and materials, making it suited for a wide range of packaging needs. This adaptability guarantees that enterprises can rely on the tester to meet all of their packaging quality control requirements.

Efficient Data administration: The ability to produce QR codes and send data in real time makes data administration and reporting easier. This increases the accuracy and efficiency of quality control operations.

Enhanced Visual Representation: The ability to play colorful GIF components creates a dynamic and interesting approach to visualize test data, making it easier for users to comprehend and analyze findings.

The Box Compression Tester Manufacturer: Testronix includes sophisticated features such as a peak hold function, a motorized model with automated platform adjusting, and safety switches with downward and upward restrictions. It is made of mild steel with a powder-coated finish, has a lead screw mechanism for increased load-bearing capability, and runs quietly thanks to robust plates. Its dual column construction allows for dynamic testing and includes choices for a computerized model, customisable platform sizes, and load cell capacity

The Testronix Box Compression Tester is designed to fit a wide range of box sizes and materials, making it ideal for a wide range of packing applications. Whether you're evaluating tiny, lightweight cartons or huge, heavy-duty shipping boxes, this tester produces consistent and precise findings. Its adjustable form provides compatibility with a variety of packing materials, including corrugated cardboard and plastic. This makes it a useful tool for businesses ranging from food and beverage to medicines and consumer products, where strong packaging is critical to product safety and integrity throughout storage, shipping, and handling.

The Testronix Box Compression Tester requires frequent checkups and care to maintain peak performance and lifespan. This involves periodically calibrating sensors and load cells to ensure accuracy, inspecting and lubricating moving parts such as the motorised platform and lead screw mechanism, and cleaning the touchscreen and controls to avoid dust collection. To minimize operating concerns, any worn-out components should be monitored and replaced as soon as possible.

Is any prior training required to operate the Testronix Box compression tester?

The Testronix Box Compression Tester has a user-friendly interface with easy programming and capacitive touch controls, making it suitable for users of various technical backgrounds. It has a 7-inch TFT LCD colour display, 16 language compatibility, mobile device remote control, and real-time data transfer. It can provide thorough reports for up to ten samples, including maximum, average, and trend graphs of load versus displacement.

To learn about the Box Compression prices, get a quotation now. You may reach out to us at +91-9313140140 or email us at info@testronixintruments.com