Is the Adhesive strength of your material hampering your production process?

In Industries such as- automotive, aerospace, packaging and electronics adhesive bonds play a crucial role in not only impacting product safety, longevity and functionality but also the structural integrity under harsh conditions. Thus, in such fields peel strength evaluation is indispensable for evaluating durability and reliability of adhesive bonds.

The purpose of the Peel strength tester is to accurately calculate the amount of force required in separating two materials joined by an adhesive. This involves estimating the adhesive’s strength as well as the overall bond quality by highlighting its potential weaknesses across varied materials and conditions.

Therefore, the manufacturers can be assured of their product’s functionality and assess the best quality materials to enhance their products and have satisfied customers.

Working of the Peel Strength Tester:

The Model design

With its sturdy metallic base and platings of chrome and zinc- the Peel Strength Tester guarantees both stability and resilience against environmental factors making the model long-lasting in diverse testing environments. By meeting ASTM standards it ensures accurate peelability by replicating real-life situations. Thus the model is intelligently engineered to satisfy all your production needs that are both accurate and efficient.

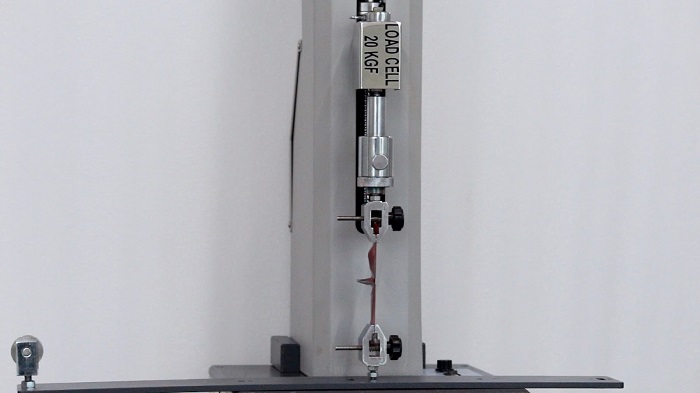

Grip Mechanism

To avoid any slippage or mistakes during the testing process, the specimens are securely placed between the upper and lower grips which are specially designed for firm clamping ensuring their security. Thus, its advanced grip mechanism is crucial for the functioning and success of the Peel strength tester. Hence maintaining both structural integrity as well as efficiency.

Stimulating Real-Life environment

In real life, adhesives are commonly employed in scenarios that test the peel’s angle and speed. Thus a simulation is created that replicates the same with the model and has predefined features that are crucial in evaluating the peelability of materials under situations that are similar to their intended application. Hence providing the manufacturer insight into the adhesive’s performance and durability in practical use cases.

Application and Features

Accuracy

ASTM standards are met by testronix to ensure accurate Peel strength test. By precisely measuring the force necessary to separate materials, it offers trustworthy data critical for quality control and regulatory compliance.

Simplified

The tester was created with the user in mind, and the controls are straightforward to use. Its straightforward setup approach allows users to swiftly arrange specimens, fasten grips, and begin testing with ease. Hence it qualifies as user friendly by reducing manual labour and enhancing accessibility.

Durability

The model’s lasting lifespan is made possible by its powder coating and corrosion resistant body to meet its testing requirements. Hence helping the instrument both adapt and remain efficient in its functioning with accurate results.

Comprehensiveness

Each Testronix Peel Adhesion Strength Tester comes with a complete documentation package. This includes an instruction manual, an electrical wiring schematic, and a calibration certificate from NABL-accredited laboratories. These papers not only make suitable setup and operation easier, but they also attest to the instrument's calibration accuracy, which increases trust in test findings and compliance with quality assurance processes.

Other features-

- Microprocessor based display for accurate test results

- It Displays the Peel Adhesive strength of test sample

- Highly accurate test results under force.

- Strong gripping clamps are used to perform this test

- Bright LED display

- Inbuilt calibration facility

- Feather touch controls

Benefits of using the Peel Tester

Enhanced product quality

By properly measuring peel strength, the tester guarantees that adhesive bonds fulfil high quality standards. This skill assists in recognising possible difficulties early in the manufacturing process, avoiding faulty items from reaching consumers, and improving overall product reliability.

Cost savings

The tester's exact measurement lowers material waste and rework, which improves production efficiency. Furthermore, its sturdy design and dependable performance reduce the need for periodic recalibration or replacement, decreasing long-term operational expenses.

Regulatory compliance

Meeting ASTM standards and giving approved calibration certifications guarantees that Peel tester findings are accurate and in accordance with industry norms. This builds confidence with regulatory agencies and consumers alike, indicating a dedication to quality and durability.

Versatility and flexibility

The tester is versatile in evaluating numerous adhesive applications and is applicable to a wide range of materials and industries, including packaging, automotive, and electronics. This adaptability enables businesses to use the device on several production lines and applications, unifying testing procedures and streamlining operations.

Improved Decision Making

Accurate peel strength data allows for informed decision-making throughout the product development and manufacturing stages. Whether testing novel materials, optimizing adhesive formulas, or resolving production concerns, the tester gives vital insights that drive continual improvement and innovation.

FAQ’s:

What maintenance is required of the Peel strength tester?

Regular calibration from NABL approved labs and adherence to the manufacturer's suggested maintenance methods will maintain the tester's optimal performance. Ensuring industrial standards, accuracy and longevity.

What prior knowledge or training is required to operate the model?

With it’s advanced intuitive controls and comprehensive manuals and directions the testing process is both simplified yet efficient. Committed to providing you the best of both worlds.

What Industrial standards does the tester comply with?

By complying with the ASTM standards - the model is considered to be durable, corrosive resistant as well as user friendly along with calibrated certificates making it the perfect addition for your production process.

DON'T MISS GETTING YOUR PEEL STRENGTH TESTER!

To know the Peel strength tester’s price get a quotation now. You may reach out to us at 9313140140 or email us at info@testronixintruments.com