Reviewed by Anurag Mishra (Sr. Technical Consultant)

Paper gloss is a well demanded feature in magazine and for photograph paper. The gloss in paper has many more application than that too. For different application the manufacturers have to set a required amount of gloss which fulfils their purpose of glossy appearance. To test the gloss reflection and fix a particular amount of required gloss on papers, manufacturers required to measure its gloss properties with Tri-angle Method in Gloss Meter. This method includes testing the specimen from three different angles, which are 20, 60 and 85 degrees. The measurement type is considered to be an ideal method for Paper gloss measurements.

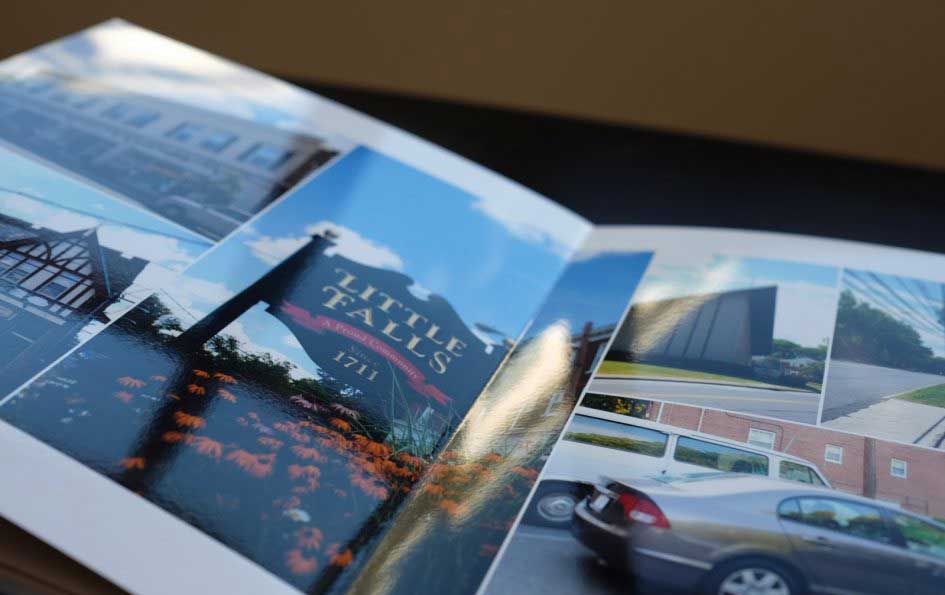

The paper material used for making magazine or printing photographs are kind of glossy but the gloss factor is controlled throughout the product and differ from other products. For instance the Gloss factor in amazing paper must be same throughout the magazine. If it differs then the quality will hamper. Imagine a reader while going through the magazine find one or two page whose higher gloss then expectance has reduced the readability and few pages whose, Gloss property is so low that they does not match the standards of the magazine manufacturers.

Same with the paper used in printing photographs. If the gloss is too high then it the picture will not be clear to see and if the gloss is too low, it will not appear good. Gloss meter is a highly advanced equipment which measures the gloss reflection from the specimen surface at three angular levels. The device has automated calibration features to deliver complete accuracy in the test results. Has a captivating touch display which is used in both way for operation and test monitoring.

The screen helps the user to set the testing mode, angle and other parameters, also it shows the monitored test results on the screen. The test machine complies with several international testing standards such as ASTM D2457, ASTM D523, ISO2813, and GB/T 9754. The test results are output of software-based data. The chances of errors is zero with the device. You can see that with repeatable measurements too.