Reviewed by Anurag Mishra (Sr. Technical Consultant)

The coefficient of friction is a key factor in determining how easily one surface moves against another. When the coefficient of friction value is higher, a higher force is required to slide one surface to another (like brake pads on a wheel). Similarly, lower friction means a low force requirement for the same task (like ice on metal). Understanding friction behavior is essential for designing safer, more efficient designs in engineering, manufacturing, and transportation.

The coefficient of friction (COF) measures how much two surfaces resist sliding against each other. It is a dimensionless number measured as the ratio of friction force and normal force. A higher COF indicates greater resistance to motion, while a lower COF means surfaces slide more easily. It depends on material properties, surface texture, and external conditions, and applies to everything from industrial machinery to everyday tasks.

The formula for the coefficient of friction (μ) is the ratio of friction force to normal force and is written as follows –

Let's break down the basic formula used to calculate friction:

Here, μ (mu) is the coefficient of friction, it is a dimensionless number.

F is the force of friction existing between the surfaces.

N is the normal force or the force that acts perpendicular to the surfaces in contact.

The coefficient of friction is critical in plastic films; if too low, the film may be too slippery and, therefore, may cause handling problems during shipment. If too high, the film sticks both to itself and other surfaces, causing jams in machinery and therefore causing production slowdowns.

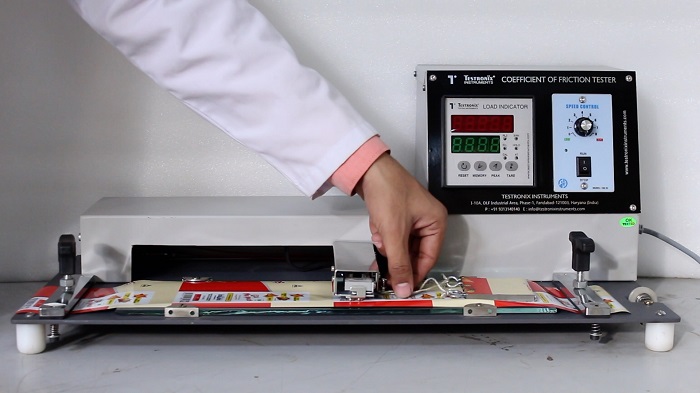

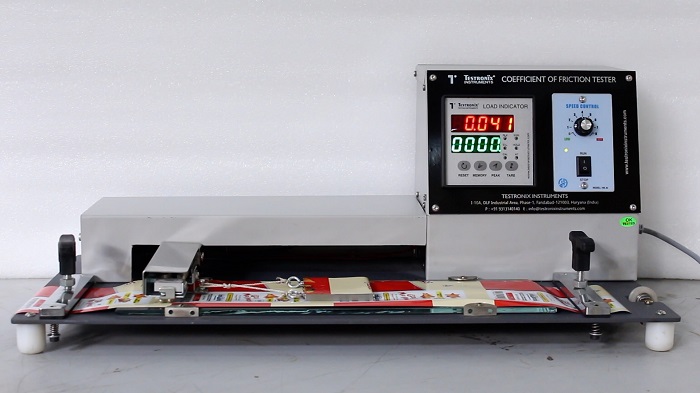

If you want to make sure your plastic films have the proper COF, then you should be measuring a proper one. Here, the Coefficient of Friction Tester comes into play.

A Coefficient of Friction Tester is a dedicated device for measuring friction between two bodies. It delivers the measurement known as the coefficient of friction, which quantifies the degree to which one surface causes or can resist friction relative to another. This tester is very important in industries where friction needs to be understood and controlled, like in automotive, packaging, textiles, and buildings.

The beauty of the coefficient of friction is that it has no units at all because it's a ratio of two forces - measured in Newtons. Thus, the units cancel each other out.

In theory, this makes the COF just a pure number, easy to compare across materials and different scenarios.

The Coefficient of Friction Tester is a very important gadget for many industries, whose importance cannot be overemphasized. Here's why it is so vital:

The COF tester ensures that materials possess uniform friction characteristics. The uniform friction characteristics are essential in ensuring the quality of a product remains the same in various batches of its production.

The knowledge of the COF of materials helps manufacturers to optimize such materials for a specific application. Here, in the case of packaging, the appropriate COF would ensure that products cannot slide while in transportation to prevent them from being broken.

Material with incorrect COF can jam or slow down machinery, leading to delays in forming products. Materials with COF pre-tested machinery compatibility ensure there is an assurance of smooth equipment operation, which improves the general efficiency scale.

There will be no material failure due to the COF test, and the production process will be streamlined, thus saving a great deal in terms of downtime, repair, and the material itself.

In many applications, the wrong COF has a tendency to cause accidents such as a product slipping from its position, or even machinery malfunctioning. Regular COF checking saves the day in the prevention of such accidents.

Correct COF data will enable the engineer or designer to make better decisions on the selection of materials and design of improved products.

FAQ's

The material, surface texture, temperature, and lubrication are probably the most common factors that may influence COF. Even small differences in any of these variables can be responsible for very big differences in the frictional behavior of a system.

Yes, COF can vary with wear, deterioration, contamination, or changes in the surface condition. Testing is needed to ensure performance on a regular basis.

Most modern testers permit measurement for both static and kinetic friction, thus giving one the full picture of the friction behavior of one's material.

HERE’S A CHANCE FOR YOU TO SECURE YOUR SUCCESS!

Phone: +91 9313 140 140