Reviewed by Anurag Mishra (Sr. Technical Consultant)

Adhesion is the property of materials that determines how the material will bond. In industries such as rubber, adhesives, and coatings, knowing the power at which bonds of one material hold to another has become particularly important to the safe, effective, and long usage of final products. ASTM International develops standardized test methods known as ASTM D429, which measure the adhesion strength of rubber and other rigid substrates, including metals and plastics.

Manufacturers will face total disaster if they fail to comply with the ASTM D429 standards. Without such vital tests, industrialists can face reduced product performance and customer complaints, and increased costs due to product returns and warranty claims.

If the rubber-to-rigid substrate bond strength is checked, the manufacturers will be able to ensure the workability of their adhesive products when exposed to forces experienced in real-life conditions.

ASTM D429 testing may be required to ensure product reliability, durability, and user safety. The manufacturers may guarantee the safety of their products by complying with ASTM D429, which reduces the chances of failure and potential legal or reputational repercussions.

Another important aspect of ASTM D429 is testing the compatibility of rubber with other rigid substrates. The standard allows a company to ensure that the chosen materials are suitable for bonding, preventing problems of material mismatch, poor bonding failure, or excessive wear under normal conditions.

For the testing equipment of the best quality, We are regarded as a go-to entity. The basis for this is that we help by offering advanced and reliable testing instruments to ensure that accurate results are delivered through equipment that is easy to use.

We have earned an excellent name and are regarded as one of the most trusted names within the industry, providing bottle torque testers along with other testing instruments that come with performance, precision, and reliability.

ASTM D429 consists of six different test methods. They all differ in adhesive and substrate configuration. We detail the following with a few brief descriptions:

This technique estimates the grip strength when the elastic is clung to an unbending substrate at the right point. This is measured by a sample of either 90° peeling or recording the force necessary to break the bond. This test is quite standard for adhesive bonds that have a flexible material like rubber or plastic.

In this process, the bond is peeled straight in a direction at an angle of 180°. This technique is rather widely used for the testing of coatings and adhesives where the bond is designed to withstand forces that are trying to peel it away in one specific direction.

In the shear test, the grip is estimated by shear pressure. It is the force applied lined to the adhesive bond. The test measures how strong a bond can hold when forces are applied to make one material slide over the other, an effect similar to friction or sliding stress in reality.

This method measures the maximum tensile strength required to break the bond. It can be applied to assess the resistance of the bond to tensile forces, similar to those that occur in service in cases where the adhesive is loaded in tension, for example in components for the automotive or aerospace industries.

Samples are submerged in chemicals for the evaluation of adhesive bonding's durability after exposure to various liquids. This is similar to the environment in practice, where the adhesives may be exposed to oils, solvents, or other aggressive chemicals.

This test tests the behavior of adhesive bonds at an elevated temperature. This is particularly important for applications where temperature changes occur, including as part of an engine or machinery.

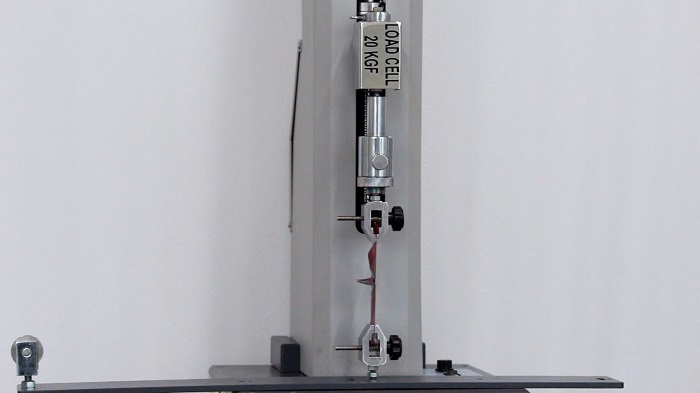

In ASTM D429 testing, instruments could be the peel tester, tensile tester, and shear testing machine.

Peel Testers: These are intended for use in measuring force to peel adhesives at different angles, namely 90° or 180°. They are good instruments for applications such as packaging or automotive bonding.

Tension Testers: These testers ascertain the extent to which before break-up an adhesive bond can tolerate tensile forces. They are extremely prevalent in all applications that require strength under tensile forces.

Shear testing machines: Such machines are used when applying shear forces and testing the resistance to the sliding stress of the bond. These machines are of immense significance wherein lateral or shear stresses in adhesives are likely to develop.

Calibration of the testing equipment is a must and a promise to ensure constant and accurate results during testing.

Preparing Sample: The preparation of samples should strictly be according to a guideline, which states the right thickness, shape, and quality of adhesive bond at the conjunction points. Any change would lead to an inaccuracy in the test results.

Testing Environment: Certain factors like temperature, humidity, and sample handling can largely affect the test results. ASTM D429 requires testing under a uniform environment, thus all recorded data is reliable.

Testing Method: The specimen is mounted in the testing machine to which the test force as prescribed in the selected test method is applied. Results are reported in terms of the force required to cause failure via either adhesively or cohesively failing bonds.

This is a standard test intended for the bond strength among elastic and a solid substrate, which can be made of metallic or plastic material.

Adhesion testing ensures that bonds withstand stress and environmental conditions over time, guaranteeing that the products will be safe, reliable, and effective in service.

Peel tester, tensile tester, and shear testing machine are commonly used equipment.