It is very important in material testing to determine how materials will behave under stress. In determining plastic toughness, a standard test applied is one referred to as the ASTM D256, also known as the Izod Notched Impact Test. Through this standardized test procedure, it can be determined if plastic materials have a lot of resistance to impact and thus a very important attribute of such materials when used in highly demanding environments.

It determines the energy with which a notched plastic specimen should be broken by a pendulum strike to understand the durability and resilience of plastic materials under various conditions.

Impact Resistance of Plastic Materials

Impact resistance is one of the significant performance characteristics in using plastic materials for industries such as automobiles to consumer electronics. Plastic parts are often exposed to impacts or stress loads in service that are applied suddenly, and poor resistance can result in cracking or complete structural failure.

Using ASTM D256 Izod testing, manufacturers can consistently measure the impact resistance of plastic material so that they may select materials that will ensure a long service life and safety in applications. Aside from safety, testing also gains confidence on the part of consumers. Testing ensures that end-users are assured that the materials used have been tested for their strength and resistance to impact stresses.

Testronix: Seizing Power in Material Testing

Testronix has been one of the trusted names in the material testing industry for more than 11 years and has made great contributions to the plastic impact testing area. Precision has always been the watchword at Testronix, with Izod impact testers used by manufacturers to obtain precision in their quality control processes. Here's what makes Testronix different:

Proven Expertise:

Since the company has over ten years of experience in testing materials, it has perfectly streamlined the equipment and testing procedure for different client requirements. Over time, this practice makes sure that Testronix devices comply with ASTM D256 standards, allowing users to receive accurate results without errors.

Customer Success Stories:

Leading manufacturers of plastics rely on Testronix for plastic impact testing. One example is a customer who, recently, used the Izod impact tester by Testronix to determine the toughness of a newly developed biodegradable plastic material in order to enhance product quality and thereby avoid field failures of products.

Customer Testimonials:

The majority of the customers praise that Testronix has a strong design, accuracy, and very good after-sales service. Testimonials of the clients about the usability and durability of the equipment from Testronix make it obvious why the material testing engineers like to use the brand.

Method and Equipment Used

The Izod Notched Impact Test is standardized in its methodology, and the tests give repeatable and comparable results. It briefly operates as follows:

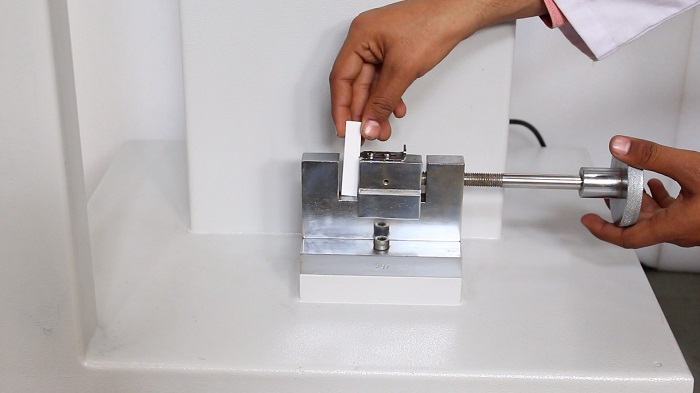

Preparation of Specimen:

A notched specimen of the plastic material is prepared with precise dimensions as specified in ASTM D256. The notch is a small groove that serves as a stress concentrator and models real defects in materials.

Pendulum Swing:

The sample is mounted vertically with the notch toward the pendulum. It is released from a particular height and swings down to hit the sample at a precisely defined point. Such a controlled impact simulates the slamming events that materials experience in service.

Data Collection:

The machine determines the energy absorbed by the specimen in impact and gives an Izod impact value. Data shows the toughness of plastic, and high values are good indicators of impact resistance.

Comparison of Izod with Other Impact Tests

Even though the Izod test provides significant data about the impact resistance, there are other impact tests also that are used and provide other types of information:

Charpy Impact Test:

This test is also called Izod, where the specimen is mounted vertically. In Charpy, however, it is mounted horizontally. They both employ pendulum impact, but due to the orientation of the specimen, the results may vary in one test which could affect the suitability of Charpy for materials best to experience horizontal stress loads.

Gardner Impact Test:

This is often used to determine plastic impact resistance for films or coatings that are thin. The Gardner tests involve a weight dropped onto the material surface and give another type of impact data, especially for materials with a low thickness or coatings where lateral resistance might be different.

Drop Weight Test:

This is the most frequent one for thicker materials by the dropping of a designated weight from a fixed drop height onto the surface. Not as standardized but preferred on certain occasions to gauge resistance that happens in real impacts due to falling or dropping the item.

The selection of proper tests depends upon the intended applications of the material and conditions under which they will suffer stress, thus giving the manufacturers a greater picture of any material's behavior in certain conditions.

FAQs

1. What is the use of the ASTM D256 test?

The ASTM D256 is a standard test to find the impact strength for the determination of resistance of plastic materials. It does this by measuring the absorbed energy in a controlled impact. The result indicates how tough and durable the material is.

2. What do you understand by the terms Izod and Charpy impact tests? How do they differ from each other?

The Izod test holds the specimen vertically, whereas the Charpy test mounts it horizontally. This difference in orientation affects the way each test measures impact resistance and makes them applicable to different material applications.

3. Why is impact testing important for plastics?

Impact testing determines a plastic material's resistance to sudden stress, thus preventing product failure and ensuring consumer safety in actual application.

Contact us

Phone: +91 9313 140 140