Reviewed by Anurag Mishra (Sr. Technical Consultant)

Salt spray testing is among the most critical methods to estimate the corrosion resistance of surface treatments, coatings, and metals, and guarantee the durability of products. All the Testronix Instruments adhere strictly to ASTM B117, the globally recognized salt spray (fog) testing standard. The standardized test is performed in a controlled environment to determine the material's corrosion resistance and is frequently employed in the automobile, aerospace, and manufacturing sectors.

With the help of standards of ASTM, manufacturers like us provide accurate and stable test results, allowing our customers to enhance product quality, extend lifespan, and guarantee conformity to industry standards.

ASTM refers to the American Society for Testing and Materials, which provides standard practice for environmental and engineering services. The ASTM B117 is one of the most common standards for the salt spray test that defines certain parameters and specifications to perform the salt spray test in specific environmental conditions. This standard practice for operating salt spray apparatus must be followed by various industries, including –

ASTM B117 is not restricted to salt spray operations only but also outlines the best practices for apparatus requirements, types and preparation of test specimens, temperature conditions, the timeline of the exposure period, etc.

The ASTM B117 standard is designed to ensure the material’s durability and to test how well the material resists corrosion when exposed to salt water. Here, B is referred to as “Non-ferrous materials,” and 117 is an “assigned sequential number.”

It is a detailed and standardized document with various parameters and guidance, including the following:

It is important to note that ASTM B117 does not predict real-world corrosion performance. It provides a standardized environment for comparing materials under accelerated/stimulated conditions.

Standard practice for salt spray testing is utilized to generate consistent and reproducible results. It provides detailed guidelines for the apparatus to be used, how testing is to be conducted, and how the conditions should be controlled to mimic the required environment during salt spray testing. Here is the detailed standard practice for operating salt spray fog apparatus –

The scope of ASTM B117 standard practice in various industries regarding the operation and testing procedure of salt spray test. The standards work as the guidelines for the technicians or operators that include the following important clauses –

To perform the test accurately and as per the ASTM standards, the preparation and positioning of the test specimen is critical. The following are the important clauses of standard practice to be followed while using the specimen as per the ASTM B117 standard –

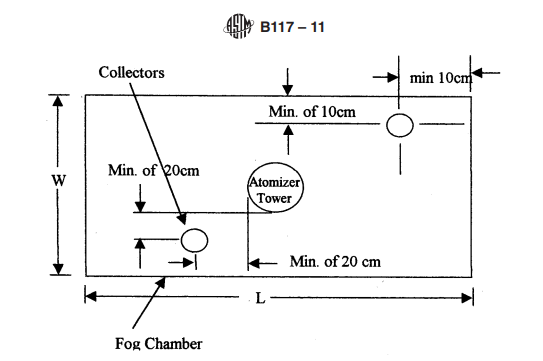

Once the specimen is positioned, the next crucial step is to set up the salt spray chamber which is the core of the entire standard practice. B117 describes how to set up the apparatus and what are the steps to be followed for accuracy –

The salt solution shall be prepared by dissolving 5 (+/-1) parts by mass of sodium chloride in 95 parts of water conforming to Type IV water. Here are the comprehensive steps to be taken as per the ASTM B117 standard –

Test monitoring is the internal function of salt spray testing and ASTM B117 comprehensively documented how to monitor the test and results. Here are a few standard practices to be followed by operators –

In various conditions; continuous uses of apparatus, the equipment may not deliver accurate results, so maintenance is paramount before testing. The following are the guidelines outlined by ASTM standards –

Quick Summarization Standard Practice –

ASTM B117 standard is a vital guideline for operators who indulge in salt spray testing. Apart from accurate results, following the ASTM standard practices comes with below-mentioned advantages –

ASTM B117 is used in various industries and is the most followed ASTM standard for accurate and reliable results but it has some limitations as follows –

Does Not Imitate Realistic Scenarios – The test accelerates corrosion but fails to accurately reproduce realistic scenarios like exposure to the sun, humidity fluctuations, or contamination.

Does Not Simulate All Types of Environment – Even though ASTM B117 standards are heavily used in various industries, they lack to simulate specific environmental conditions like acidic, alkaline, and UV radiations.

Too Aggressive on Some Materials – Some coatings pass the test but others do not as they overly perform in actual service conditions with some materials.

Even though ASTM B117 is the most used and standardized guideline for salt spray tests and other test procedures, the following standards are often used –

Industries that frequently conduct Salt Spray Tests or utilize salt spray (fog) apparatus must align the best practices outlined by ASTM B117 and other critical standards. With standard practices, including proper sample preparation, solution preparation, chamber calibration, and regular maintenance, industries can achieve consistent and reproducible results.

Testronix Instruments follows standard practices for operating salt spray (fog) apparatus, and all our products align with ASTM standards, including B117. Industries can trust our high-quality equipment, including salt spray testing, to get reliable and precise results. For more information, Contact Us or Get a quote.