Reviewed by Anurag Mishra (Sr. Technical Consultant)

Corrosion and rusting are culprits that can cause more damage to your brand’s reputation, than your products. Industrial use metal components, automobile parts, pipes, fittings & coated panels should be tested for corrosion resistance.

Using a comprehensive and reliable piece of equipment called Salt Spray Chamber, is a simple yet effective way of ensuring high quality and durability.

It is a necessary instrument, used to evaluate the resistance to corrosion of coatings, paints and small metal objects, including mechanical parts.

The sample is placed in the salt spray test chamber. Here, the sample under test, is exposed to a very intensive salt-based atmosphere for a specified period. The Salt Spray Test Chamber is designed to replicate or simulate environmental conditions. Thus, they considerably accelerate the corrosion process.

As per industry standards, the time specified for testing is 240 to 1000 hours, for the purpose of corrosion testing. However, this period can be customized according to specific requirements.

Testronix Testing Instruments manufactures and provides one of the best Salt Spray Chambers in India. The chamber conditions and the salt are specified by various industrial standards to perform salt spray testing. The quality of salt used is as per the purity standards. This ensures that latest requirements are met.

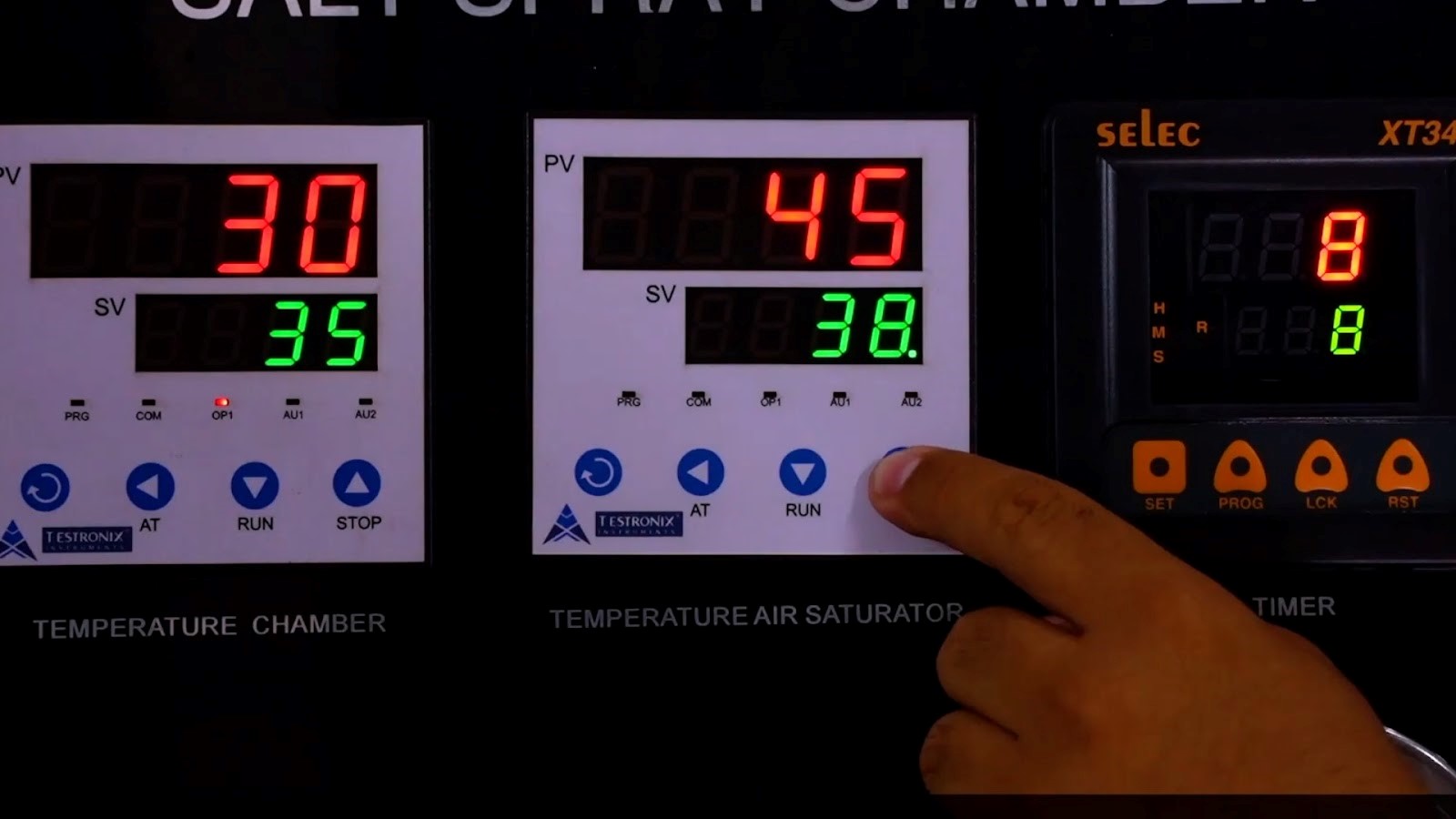

Testronix Salt Spray Chamber adheres to ASTM B117 and JIS Z 2371 standards. The chamber consists of an atomizer, which ensures an even distribution of salt spray. A timer is also fitted to ensure accurate sample collection rates throughout the test cycle.

For more details regarding features and price, please visit: https://www.testronixinstruments.com/salt-spray-chamber-frp-digital/

Utilized to perform corrosion testing on a wide variety of samples, the Salt Spray Testing Chamber is used for:

Widely used in various industries, Salt Spray Testing is especially useful in:

Corrosion resistance of parts or finished surfaces can be easily evaluated using this test.

It is, therefore, important to ensure that all components are thoroughly tested and documented for their corrosion resistance.

Salt spray test results are a reliable source to understand, the impact of moisture and weathering, in terms of rusting of a product. The Salt Spray Chamber has been manufactured to create the precise environmental test conditions.

The chamber can accommodate several small metal panels or objects etc. Hence, multiple products can be tested at the same time. These test results can be further, compared scientifically in the same controlled test environment. This makes it time-effective and saves effort!

During the test cycle, the corrosion levels are monitored, at specified time intervals. This is done by opening the cabinet and taking photographic evidence of any surface oxidization. Through test cycles, the metal plate surface is examined. This is done to evaluate the corrosion and rusting of the sample.

Testronix Testing Instruments are one of the best Salt Spray Chamber Manufacturers in India. For further assistance, please visit https://www.testronixinstruments.com/ or call +919313140140 for more details and customization of the equipment.