Reviewed by Anurag Mishra (Sr. Technical Consultant)

Hi! Ever been in that heart-stopping moment when a product finally reaches its destination and the packaging well, let's just say wasn't quite up to the trip? It's frustrating and considering the costs, too! The packaging may look strong enough, but if it cannot take the bumps, drops, and tosses encountered on the way to its destination, then it is about as useful as used tissue. That's where the carton drop test comes in.

Wait for it! Before you think that I am throwing around random testing terms at you, let me explain, the carton drop test is something wherein a magic trick lies to ensure that your packaging can bear a hit-literally. And what is even better? I'm here to walk you through 6 simple steps to undertake an effective carton drop test.

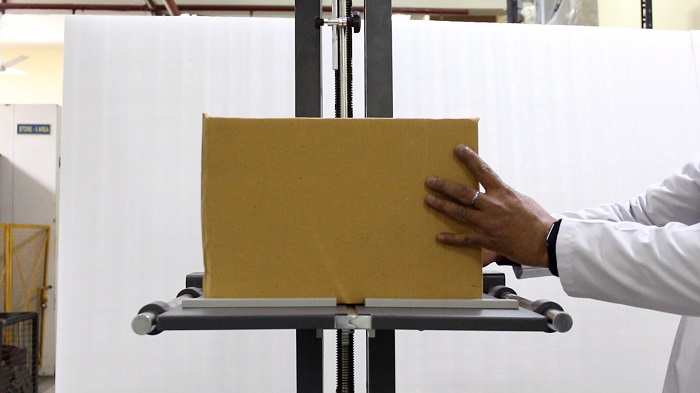

The icing on the cake? I have just the tool for that, the TESTRONIX’S DROP TESTER. Buckle up; things are about to get real!

Before we even get into the testing, let's talk about what is inside that box. The product weight, size, and fragility will play a huge role in how you conduct the drop test. Are you shipping something as light as a stack of paper? Or is it some heavy appliance that we are dealing with?

Pro tip: Your drop test setup should simulate real-world shipping conditions. That means the product is packed exactly like it would leave the factory-same product, same packaging materials, same everything. No cheat shortcuts!

Now finally it's time to let that box fall! Wait for a minute there's a method to this madness.

It goes without saying that you would have to drop test the carton on the six different front, back, left side, right side, top, and bottom. Why? Well, while in shipping, your package isn't going to land the same way every time, is it? It is going to be tossed and flipped and jostled every which way. You must test all sides!

This is where the DROP TESTER comes in with precision. It makes sure each drop is just the same, with no guesswork. The machine will drop the carton from some height so that you will know just where your packaging stands.

Now, let's discuss heights. This becomes an important issue because not every package is handled in exactly the same way. While some cartons may get a light nudge, others may actually fall seriously off a conveyor belt or off a warehouse shelf.

But don't sweat it-DROP TESTER makes that part easy with the capability to set the drop height with precision. Be it a shortfall from a loading dock or a super dramatic plunge from the top of a truck, you will get accurate, repeatable results every time.

Immediately after each drop, it's time to examine the package for any delamination, crushed corners, split seams, tears, or anything that compromises the integrity of the carton. And of course, check the product inside! If the packaging looks fine but the product is damaged, that's a failure.

This is the step that tells you whether your carton really has what it takes: can it stand the bumps and bruises of shipment, or did it fall short?

Believe me, this part won't be about just one drop. You may have to do this repeatedly until you see a clearer picture of what you are doing. In particular, this is where the DROP TESTER becomes convenient because it allows for the running of the same test over and over, and by doing so you have reproducibility, which makes your data even more comparable.

So what did the test reveal? If your carton passed with flying colors, great! You have packaging that can handle the shipping process without breaking a sweat. But if there is damage, don't freak out. That's what this is for, testing weaknesses prior to your product hitting the shelves or even the mail truck.

According to the results, you might have to readjust the design of your packaging. Maybe the walls of the box have to be thicker, or you should use better cushioning materials. Whatever the case, now you have the data to make informed decisions.

And you know what? You can do it all again and again with the DROP TESTER until you get just the right touch!

Carefully observe the outcome after performing drop tests. Check for patterns in types of damage that may occur, such as crushed corners, punctures, or breakage.

Check why the samples failed. The causes could be the strength of the materials used, design mistakes, or sizes that are improper. This damage could be compared to relevant industry standards or earlier tests to gauge performance. This may help you find out if the package meets the recommended specifications.

So, the next time you're wondering if your packaging is tough enough to make it, remember these six steps. Of course, remember the DROP TESTER- your ultimate buddy in the war on damaged goods.

KNOWLEDGE PUDDLE!

The carton drop test is one of the methods that involves exposing packages to various impacts and drops that they are likely to undergo during shipment, showing their resistance. It helps to ensure that the packaging, along with the product inside, can sustain any type of rough handling that may come about during shipment without getting damaged.

That matters immensely, as broken packaging leads to damaged products, distressed customers, and costly returns. This drop test determines the weaknesses of the packaging before the shipment so as to make your goods reach a destination safely and intact.

It is designed to bear a wide range of packaging varieties, from the tiniest lightest box to a big heavy carton. The Drop Tester houses a number of different sizes, weights, and materials for proper testing that a product should undergo.

Investment in a carton drop test is but one small step that makes a whole world of difference. And your customers will thank you, and so will your bottom line!